sulfuric acid dosing in precipitated silica production

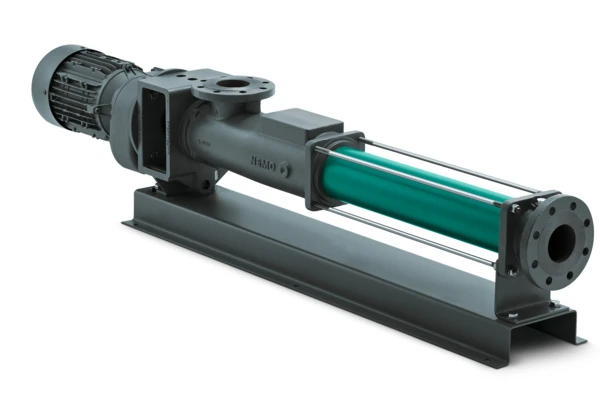

Precision dosing of sulfuric acid with NEMO® Progressive Cavity Pumps

In precipitated silica production, precise chemical dosing is essential for efficiency, cost savings, and process stability.

Sulfuric acid dosing in precipitated silica manufacturing is one of the initial steps and its accuracy plays a critical role in the entire process. At this stage of the process, the silica slurry’s pH can fluctuate due to various reasons, and it is necessary to keep it at a precise range to ensure an efficient downstream process. To achieve this, the dosing rate of sulfuric acid must be adjusted dynamically to the pH variation of the silica slurry. Accuracy was paramount since the precise dosage of sulfuric acid directly influence the process's time and efficiency.

Discover how NETZSCH’s progressive cavity pumps provided precision in sulfuric acid dosing for unmatched accuracy and reduced chemical usage.

Individual Consulting

Earlier pump technology and challenges

The dosing pump utilized was a VFD-driven metering piston pump. The reciprocating action naturally creates a pulsating flow, with peaks during the discharge stroke and drops during the suction stroke. This pulsation effect caused flow inconsistencies, making it difficult for downstream systems, such as flow meters, to read and respond accurately. The flow rate measured over time was not reliable, leading to incorrect adjustments in the dosing process. This inaccuracy was causing anomalies in the dosage and resulting in inconsistent pH levels in the silica slurry.

The associated challenge of pulsation was the over and under-compensation of dosing chemicals. Overdosing of sulfuric acid leads to excessive chemical consumption, which increases operational costs. Under-dosing could result in poor process performance, requiring corrections that consume additional time and resources.

Inconsistent dosing directly impacted batch quality, necessitating recalibrating

The associated challenge of pulsation was the over and under-compensation of dosing chemicals. Overdosing of sulfuric acid leads to excessive chemical consumption, which increases operational costs. Under-dosing could result in poor process performance, requiring corrections that consume additional time and resources.

Process delays were the main pain point because of the slower stabilization times for the pH in the silica slurry. Operators often needed to stop or slow the process to manually adjust and recalibrate the dosing pump, reducing production throughput. Inconsistent dosing directly impacted batch quality, sometimes necessitating rework.

NEMO® Progressing Cavity Pump, the optimal dosing solution

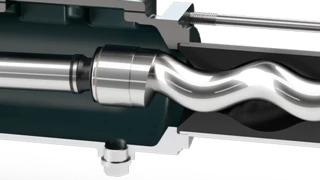

Unlike metering pumps, Progressing cavity pumps provide continuous, linear, and pulsation-free flow, offering exceptional dosing accuracy.

- The pump’s unique design ensures smooth and uninterrupted flow, eliminating pulsations that previously hindered flow meter accuracy. This consistent flow enabled precise control over the sulfuric acid dosage, ensuring optimal pH levels in the slurry.

- The PC pump maintained accurate flow rate readings, aligning perfectly with the variable inlet silica slurry flow. This improved the dosing pump's responsiveness to real-time process conditions.

- Precise dosing eliminated overuse of sulfuric acid, reducing chemical costs and minimizing environmental impact.

- The streamlined dosing process reduced delays, optimizing production time and boosting overall efficiency.

- Built to handle chemically challenging media like 98% sulfuric acid, the NETZSCH pump demonstrated superior durability and operational reliability.

By installing the NEMO® progressive cavity pump, the silica manufacturer experienced a transformative improvement in their process. The pump delivers uninterrupted, highly accurate, and precise flow and the transmitters ensure accurate sulfuric acid dosing.

This accuracy maintained optimal pH levels in the silica slurry, resulting in consistent product quality and significantly reducing sulfuric acid consumption, which lowered operational costs.

The pump’s pulsation-free performance eliminated process delays, enhancing overall production efficiency and streamlining operations. This comprehensive solution not only addressed the previous challenges but also established a more reliable and cost-effective dosing system.

NETZSCH’s NEMO® progressive cavity pump proved to be a reliable and the best choice for precision dosing solution for handling 98% sulfuric acid in a critical industrial application.

NEMO® Progressing Cavity Pump

- Medium: Sulfuric Acid

- Delivery rate: 1,500 to 5,000 kg/h