FKOD Vessel emptying in oil & gas Storage and Pipeline systems Engineering

Pump Solution for Emptying FKOD Vessels

A reputed EPC Contractor for Oil & Gas Storage and Pipelines company was into design and engineering a flare system for a bulk storage terminal project and need pumps to empty the flare knockout drum (FKOD) vessel, an integral part of a new high-pressure flare system. These large vessels, part of the flare system, capture and remove accumulated liquids that condense during the ordinary expulsion of relief gases. FKODs are essential components of industrial pressure relief systems at gas and petroleum sites. Also called vapor liquid separators or knockout pots, liquid knockout drums are standard components in all flare systems and play a crucial role in safe operations.

As a global specialist in complex fluid management, NETZSCH Pumps & Systems has successfully emptied FKOD Vessels in the Oil & Gas storage and pipeline systems with progressing cavity pumps.

Individual Consulting

Flare Systems

Flare systems generally require a flare knockout drum to separate liquid from gas and to hold the maximum amount of liquid that can be relieved during an emergency situation or maintenance activities. Knockout drums are typically located on the main flare line upstream of the flare stack.

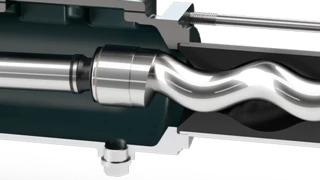

All flare systems are designed to include a liquid knockout drum vessel. These vessels are either above grade or at below grade, and typically operate at certain vapor pressures. There is often not a lot of energy to get the fluid into the pump suction. While centrifugal pumps are used in these applications, centrifugal pumps are often susceptible to cavitation. In this project, the fluid was light oil/condensates (C5+) with a low viscosity of 0.2 - 0.7 cP and a vertical NEMO® BT progressing cavity pump was chosen.

Optimized Pump Solutions

At NETZSCH, we understand the challenges our energy and petrochemical customers face including pipeline, effluent, safety, storage, and discharge issues. Typical pumping solutions often include centrifugal pumps which require higher available net positive suction head (NPSHa) levels. However, NETZSCH progressing cavity pumps provide better suction capabilities at lower required net positive suction head (NPSHr) levels than centrifugal pumps and other types of positive displacement pumps.

As experts in pressure profiles from pump suction to discharge, we have mastered the dynamic relationship between NPSHa derived by pump system configuration as a whole and NPSHr derived by each pump as a separate unit. We can help you optimize the required suction (NPSHr)—the external pressure required for the pump to operate while immersed in liquid— while also controlling the available suction (NPSHa)—the external pressure at each pump.

NEMO® Vertical Progressing Cavity Pumps

Progressing cavity pumps are a superior choice for above-grade and below-grade sump tanks. Having the pump semi-immersed in the tank allows for the capability to drain the tank down to only a few inches of liquid at the bottom.

Moreover, progressing cavity pumps are better at handling variable flow and pressure rates where the time needed to empty the tank also varies. They are also able to adapt to changes in viscosities, vapor pressure, and specific gravity. These factors influence pump performance and reliability. NETZSCH NEMO® progressing cavity pumps are ideal for managing these conditions.

Another benefit of our vertically-mounted progressing cavity pumps over horizontally-mounted pumps under an above-grade tank is that our sealing design is available to channel any leakage from the mechanical seal back into the sump. This green-friendly feature reduces the risk of environmental contamination.

The customer stated, “This pump is a great fit for pumping out underground tanks & vessels. It has been a popular choice with our clients as it provides a consistent flow rate and produces sufficient head to re-inject product into the process piping.”

NETZSCH pumps have been in operation since 2017 and the customer is very pleased with their decision to standardize on our NEMO® BT line for their FKOD vessel and sump pumps.

NEMO® BT progressing cavity pump

- Medium: Accumulated Liquids

- Temperature: 15 to 60 °C

- Flow rate: 0.9 to 6 m3/h