CETP Filter Press Sludge Transfer Pump

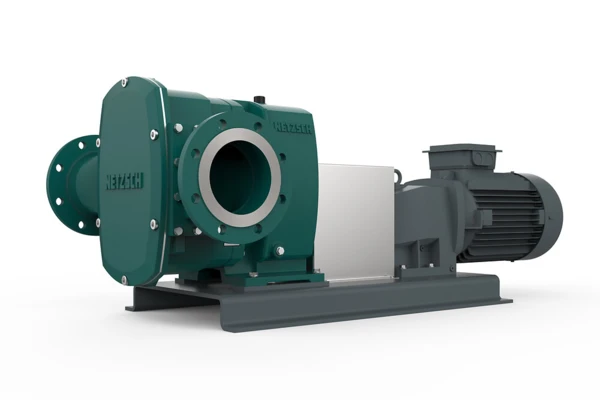

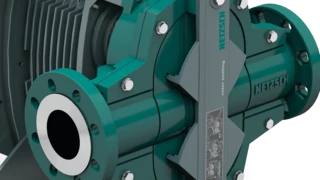

TORNADO® Rotary Lobe Pumps for CETP Filter Press Applications

In a Common Effluent Treatment Plant (CETP), that handles effluents from different sources, management of sludge plays an important role, and it also poses unique and unknown challenges. Effectively conveyance of thickened sludge to the filter press is crucial for the dewatering process. The NETZSCH TORNADO® rotary lobe pump has emerged as an ideal solution for this demanding scenario, offering dependable performance, reduced maintenance, and energy savings.

The TORNADO® rotary lobe pump offers a reliable and optimal solution for CETP filter press applications, combining energy efficiency, reduced downtime, and improved sludge handling capacity.

Individual Consulting

CETP filter press sludge handling challenges

The CETP plant operators were using a submersible centrifugal vertical sump pump for feeding sludge to filter press in the dewatering process. This pump helped in operations where it came with its own challenges. The pump required a 60 HP motor, resulting in high energy consumption. It also experienced heavy motor vibrations, frequent bottom-suction clogs, and recurring breakdowns every 2 to 3 months, necessitating frequent removal and off-site maintenance.

Due to the centrifugal design, the pump began to lose flow as the pressure in the filter press increased. When the pressure in the filter press exceeded 5 bar, the flow was redirected to a recirculation line, resulting in inefficient feeding of sludge to the filter press and poor-quality filter press cake with high moisture content.

These issues made it challenging to maintain full plant capacity, as frequent pump maintenance limited the filter press's productivity. This not only increased repair costs but also hindered the plant from operating at peak efficiency.

Reduced downtime, improved operational efficiency of CETP

Considering the installation requirements the TORNADO® Pump was proposed as a more efficient and reliable alternative.

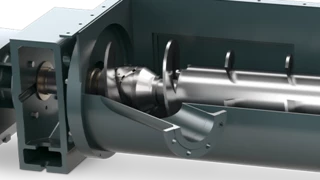

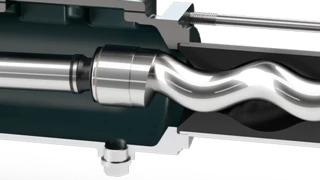

Designed to handle high-solid slurries, the TORNADO® pump required only a 25 HP motor, significantly reducing power consumption from the previous 60 HP requirement. Its advanced design, featuring wear-resistant materials and non-contacting lobe geometry, enabled smooth sludge transfer in to the filter press without flow drop during the feeding process. The cycle time reduced from 5 hours to only 3 hours, enabling the plant to function at full capacity without regular disruptions.

Another advantage of the TORNADO® pump was its ability to be serviced in place, reducing the requirement for expensive and time-consuming off-site maintenance.

This pump is designed to work effectively against pressure, which becomes especially beneficial in filter press operations. As pressure builds, the pump supports an enhanced squeezing action, resulting in a drier, higher-quality filter press cake with reduced moisture content.

The result was reduced downtime, improved operational efficiency, and enhanced quality of the filter press cake.

NETZSCH TORNADO® rotary lobe pumps results

- The significant reduction in power requirement from 60 HP to 25 HP not only nearly halved energy costs but also eased the strain on the plant's power supply, reducing the overall operational expense.

- The cycle time for the dewatering process was cut by 40% allowing the filter press to handle more batches per day, effectively increasing throughput.

- The pump’s robust design minimized downtime and maintenance costs with on-site servicing, and the pump’s design prevented frequent clogging and breakdowns compared to previous pumps.

- The pump’s ability to maintain steady, high-pressure flow improved the squeezing action within the filter press. This led to a more consistent and drier filter press cake, with lower moisture content than before.

The NETZSCH TORNADO® rotary lobe pump offers a reliable and optimal solution for CETP filter press applications, combining energy efficiency, reduced downtime, and improved sludge handling capacity. Our customer was delighted as their problem was not just solved but also brought about savings on power and smoother operations and maintenance. Its performance with high-solid, abrasive applications makes it an ideal choice for CETP plants aiming for dependable, cost-effective operations.

TORNADO® T1-F rotary lobe pump

- Medium: Effluent

- Throughput volume: 10 to 55 m³/h

- Rotations speed: 58 to 287 rpm