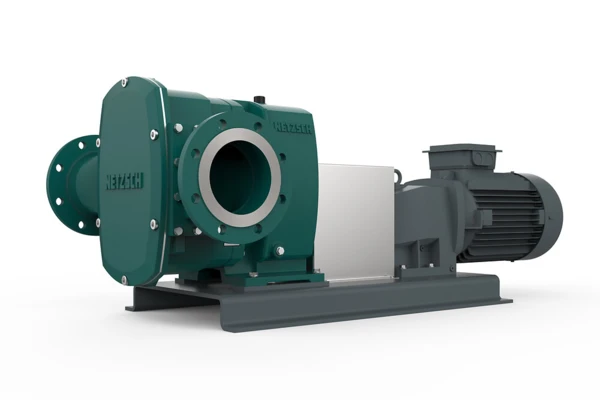

Dewatering Pump

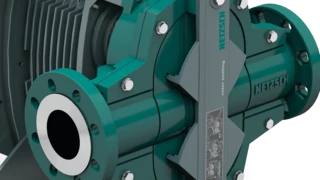

Optimize Cooling Tower Maintenance with the NETZSCH TORNADO® Rotary Lobe Pump

Cooling towers play a vital role in industries to dissipate heat from water to ensure optimal operating conditions are maintained by allowing the water to flow down through the filler material. In this process, water carry suspended solids that accumulate as sediment, sludge, and debris in cooling tower basins, over a period of time. The type of the suspended solids is based on the process of the plant.

In one of the largest steel producer’s plant, cooling tower maintenance and cleaning was a tedious task involving manpower and heavy trucks. The NETZSCH TORNADO® Rotary lobe pump, simplifies the sludge removal process thereby, reducing operational costs, and increasing the efficiency.

Explore how NETZSCH TORNADO® Rotary Lobe Pumps optimize cooling tower basin cleaning efficiently and safely with less manpower, no heavy machinery, and no downtime.

Individual Consulting

The traditional cooling tower basin cleaning challenge

The cooling tower basin at this steel plant collect a variety of solids such as iron oxide particles, slag, and dust during water recirculation. These solids settle and form sludge at the basin’s bottom, reducing water flow and potentially leading to system corrosion. Traditionally, the cleaning of these basins takes place once in every 2–3 years depending on the sludge accumulation. The basins are generally large in size and the cleaning process becomes a tedious task involving several challenges.

Reduce plant downtime reliably and safely

A minimum of 40 to 50 manpower was employed to manually get inside the tank for cleaning. The sludge and broken fins were scraped out and gathered near the pit area for the truck to remove them.

Huge super sucker trucks that use high-power airflow were deployed to suck up solids from the pit area. The rental costs of these trucks was expensive, and it also involved a lot of time and efforts in setting up the super sucker truck.

Cooling tower had to be shut down during the time-consuming cleaning process which causes disruption in the plant operation and the downtime was huge as the entire process was carried out manually.

Entry of workers in the confined space of the cooling tower basin posed risks and safety concerns. These risks involve inadequate oxygen levels, harmful gases, sudden shifts in temperature, risk of slips, trips, falls, chances of heat exhaustion and potential risk of drowning.

NETZSCH TORNADO® rotary lobe pumps - an efficient solution

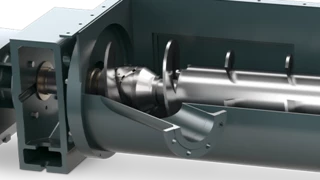

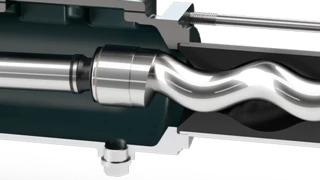

The TORNADO® T1-F Rotary lobe pumps that are designed to handle liquids with solids, made them a perfect choice for the sludge-laden environment of cooling tower basins.

Being a self-priming pump and excellent suction capability made it suitable for drawing the viscous sludge from the pit bottom. The Customer prepared to run a trial with TORNADO® Rotary Lobe Pump for five days during the scheduled shutdown. The timing was ideal, and the trial allowed the customer to assess the pump's performance without committing to major operational changes.

The pump proved during the trial by effectively handling the sludge removal and significantly reducing the cleaning time. The customer, who previously relied on large super sucker trucks and a large team for the task, found that the TORNADO® Pump is efficient and cost-effective in the sludge removal process with just a few operators.

Consequently, the customer was thoroughly satisfied. The TORNADO® rotary lobe pump is capable of cleaning the cooling tower much more efficiently and can eliminate higher engagement of heavy machines, manpower, and thereby opex costs.

NETZSCH TORNADO® Rotary Lobe Pumps have become a reliable, safe, and economical way to clean the cooling tower basin. It is also possible to clean without shutting down the operation with necessary arrangements increasing the uptime of the cooling tower. Its regular execution ensures uninterrupted pumping operations. The actual applications of this TORNADO® Pump during the trial gained customer satisfaction and made it an asset of the cooling tower in-service.

When it comes time for your next maintenance cycle, of your cooling tower basin or similar installations, consider the advantages of using the NETZSCH TORNADO® Rotary Lobe Pumps—a solution that not only simplifies cooling tower maintenance but also boosts long-term system reliability and efficiency.

TORNADO® T1-F rotary lobe pump

- Medium: Effluent

- Throughput volume: 10 to 55 m³/h

- Rotations speed: 58 to 287 rpm