10.01.2025

Lithium-Ion Battery : Energy Independence with Advanced NETZSCH Pumping Solutions

India’s Lithium-Ion Battery Boom for Manufacturing and Energy Independence

The global demand for lithium-ion batteries is skyrocketing, driven by rapid growth in electric vehicles (EVs), renewable energy storage, and consumer electronics. In India, this demand has created a powerful impetus for building a robust battery supply chain, from mining raw materials to battery recycling. With ambitious goals to electrify transportation and increase green energy adoption, India has the potential to become a major player in the global battery market. By investing in infrastructure, manufacturing, and R&D, the country stands ready to seize this opportunity, positioning itself as a critical hub for battery production, job creation, and energy security.

A Surge in Demand: India’s Role in the Global Battery Market

The battery industry’s momentum has been likened to the California Gold Rush—except, unlike gold, the battery boom is expected to continue its rapid growth for decades. According to McKinsey, the global lithium-ion battery market could expand by more than 30% annually from 2022 to 2030, reaching over $400 billion. India is no exception, with its demand expected to soar alongside global trends. Government initiatives, such as the National Electric Mobility Mission Plan and the Faster Adoption and Manufacturing of Hybrid and Electric Vehicles (FAME) scheme, are accelerating this growth by supporting EV adoption and domestic manufacturing of batteries.

Customised Consulting

The Battery Supply Chain Opportunity in India

To meet the rising demand, India needs to establish an integrated battery ecosystem. This supply chain includes:

- Raw Material Extraction and Refinement

Lithium, cobalt, nickel, and graphite are critical to battery production, yet India relies heavily on imports for these materials. To reduce dependency on foreign suppliers, the government is exploring partnerships with resource-rich countries, such as Australia and Argentina, while encouraging domestic mineral exploration. India’s mining policies are being updated to facilitate investment in critical minerals, and new ventures in material extraction are emerging.

- Manufacturing and Processing

Coping with plans to boost manufacturing capacity, India is investing in the complete battery production process—from electrode fabrication to cell and pack assembly. The Production-Linked Incentive (PLI) scheme for advanced chemistry cell (ACC) batteries aims to attract large-scale investments, and several companies have already committed to building gigafactories across India. This domestic manufacturing not only promises to meet local demand but also has the potential for exports, positioning India as a global supplier of lithium-ion batteries.

- Battery Energy Storage Systems (BESS)

Besides EVs, BESS will play a crucial role in India’s green energy transition by stabilizing power from renewable sources. With solar and wind energy on the rise, BESS installations are expected to grow rapidly, ensuring energy stability and backup for residential, industrial, and utility-scale applications. As a result, BESS is projected to expand at a compound annual growth rate of over 30% in India over the next decade.

- Recycling and Circular Economy

The scarcity and high cost of raw materials underscore the importance of battery recycling. India’s Ministry of Environment, Forest, and Climate Change has introduced the Battery Waste Management Rules, mandating collection and recycling of used batteries. Leading companies are investing in recycling facilities to recover critical materials, such as lithium, cobalt, and nickel, and India is establishing itself as a circular economy leader in battery recycling.

Challenges in Scaling India’s Battery Supply Chain

India’s rapid battery industry expansion comes with challenges, including:

- Dependence on Imported Materials

With China currently dominating the lithium processing market, India is significantly reliant on imports for essential raw materials. Reducing this dependency through alliances and domestic sources is a priority. - Equipment and Technological Limitations

Battery manufacturing requires specialized equipment, from slurry mixing to electrode coating and cell assembly. India’s growing local expertise and equipment manufacturing capabilities can cause delays. Developing a reliable equipment supply chain and training skilled technicians will be essential. - Infrastructure and Skilled Labor Shortage

Manufacturing at scale requires specialized infrastructure and a skilled workforce. Indian institutions are beginning to offer dedicated training programs in battery technology, but scaling this workforce will take time. - Environmental and Community Impact

Raw material extraction and processing can impact local communities and ecosystems. Sustainable practices and community engagement will be essential to building a responsible battery industry.

Rotary Positive Displacement Pumps: Reliable and Efficient Solutions for India’s Battery Boom

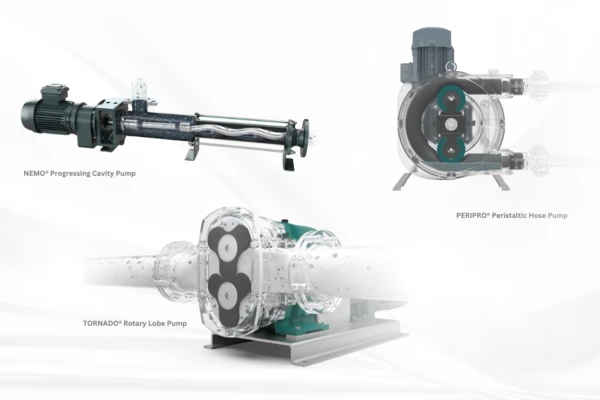

As India experiences a surge in battery production, driven by the demand for electric vehicles and renewable energy storage, the need for efficient and reliable pumping solutions becomes paramount. Rotary positive displacement pumps - progressing cavity pumps, rotary lobe pumps, and peristaltic hose pumps, handles the complex, abrasive, and viscous slurries involved in battery manufacturing and recycling. These pumps ensure precise flow control without contamination or pressure fluctuations, making them indispensable in the battery production process.

Applications in Battery Production:

- Raw Material Extraction: These pumps effectively handle viscous slurries in lithium extraction, minimizing wear and ensuring consistent operation.

- Wet Grinding and Mixing: They offer high abrasion resistance and metering accuracy, vital for preparing fine material particles used in battery electrodes.

- Electrode Coating: The Rotary Positive Displacement such as the NEMO Progressive Cavity Pumps ensure uniform slurry distribution during electrode fabrication, supporting consistent battery quality.

- Battery Recycling: The NEMO Progressive Cavity Pumps pumps handle complex, abrasive mixtures in recycling processes, enhancing efficiency and reducing costs.

- Battery Assembly & Encapsulation: During cell assembly, these NEMO pumps deliver controlled electrolyte injection and apply adhesives, sealants, and thermal management materials with precision, improving battery quality and safety.

NETZSCH Product Portfolio:

NETZSCH, a global leader in fluid management solutions, offers a comprehensive range of pumps tailored for the battery manufacturing industry:

- NEMO® Progressing Cavity Pumps: Engineered to handle intricate demands, including precise handling of electrode slurries, electrolytes, adhesives, and sealants. These pumps ensure consistent, pulsation-free flow, crucial for uniform electrode coating and accurate electrolyte injection, thereby enhancing battery performance and safety.

- TORNADO® Rotary Lobe Pumps: Designed for aggressive, viscous media with high solid content, making them ideal for raw material extraction, slurry handling, and electrode coating processes.

- PERIPRO® Peristaltic Hose Pumps: Suited for highly abrasive and chemically reactive slurries, these pumps are ideal for electrolyte injection, mixing, and precise metering, ensuring a pulsation-free flow that enhances process control and battery performance.

Future Outlook: India’s Path to a Sustainable Battery Ecosystem

The lithium-ion battery boom presents a transformative opportunity for India. By building a robust battery ecosystem, India can position itself as a leader in the global energy transition, benefiting from new manufacturing hubs, job creation, and greater energy independence. With an emphasis on sustainability, technological innovation, and partnerships, India’s battery industry is set to fuel its electrification journey for decades to come.

In summary, India is well on its way to becoming a key player in the global lithium-ion battery market. With proactive policies, strategic investments, and technological advancements like progressing cavity pumps, India’s battery supply chain has the potential to power a greener, more resilient future for the nation and beyond.