18.02.2025

Low maintenance time and Costs: NETZSCH Pumps offerings to Municipal Wastewater Treatment Plants

Optimal Model will extend the Progressing Cavity pump’s life

Reducing maintenance costs and extending pump life is essential for municipal wastewater treatment plants. Progressing cavity pumps, in particular, must handle a wide range of challenging materials, including abrasive sludge, corrosive chemicals, and suspended solids.

NETZSCH Pumps & Systems has developed innovative solutions that prioritize low maintenance, durability, and efficiency, designed specifically for wastewater treatment facilities. This article explores key design considerations and features of NETZSCH NEMO® progressing cavity pumps that contribute to lowering maintenance costs and extending pump life.

Customised Consulting

Design is Key to Lowering Maintenance Costs

In wastewater treatment, the choice of pump and its configuration has a profound impact on long-term operational costs. Design considerations like pump speed, drive configuration, sealing options, joint types, and piping systems can significantly affect both maintenance frequency and pump life.

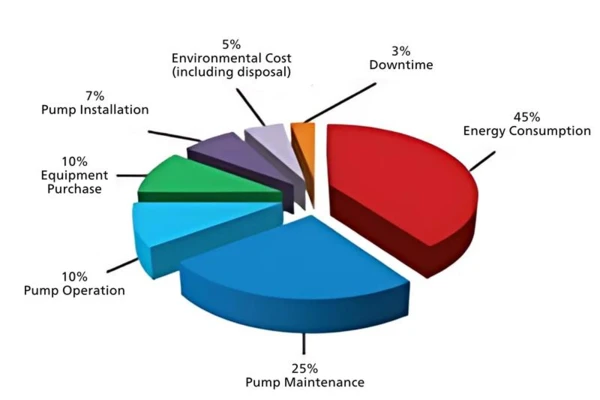

According to industry guidelines, around 80% of equipment lifecycle costs in wastewater treatment stem from maintenance, operational, and energy costs. Only about 10% goes towards initial purchase. Therefore, choosing a pump designed for durability and efficiency is crucial to reduce these ongoing expenses.

Essential Design Considerations for Progressing Cavity Pumps

- Optimized Speed and Drive Configuration

- Speed: Operating a progressing cavity pump at lower speeds can substantially reduce wear. Higher speeds often lead to faster wear and increased maintenance needs, while slower speeds extend component life and reduce frequency of repairs

- Drive Configuration: NETZSCH pumps offer both direct-drive and bearing-shaft drive, allowing operators to select the configuration best suited for their space and pressure requirements. Bearing shaft drive, while adding to the pump's length, provide robust support for handling high-pressure applications, while direct drives work well for low-pressure systems in limited spaces.

2. Advanced Sealing Options for Leak Prevention

- Seal failures: Seal failures are a common cause of maintenance in wastewater pumps due to exposure to abrasive or corrosive fluids. NETZSCH provides multiple sealing solutions that help avoid leaks and extend pump life, including:

- Mechanical Seals: Double-acting seals provide enhanced leak protection, particularly useful in abrasive applications

- Magnetic Drives: These eliminate the need for seals, providing a leak-free solution and reducing seal maintenance.

3. Innovative Joint Technologies for Durability

- The joint to be used depends on the pump size, loading, and operation. For smaller pumps, universal pin joints or V Pin joints are provided. Pin joint longevity can be increased, however, with a double sealed joint option or the covered seal joint option which protects against abrasion and sharp objects but, for larger pumps, additional joint options are available.

- Pumps that will operate with many stops and starts may function more effectively with a gear joint. Double-sealed, oil-filled gear joints are preferable to those using grease; oil refills and replenishes itself, whereas grease, once pushed out, do not replenish. This makes for a more robust, long-life joint, that will tolerate frequent stops and starts (>3-4 starts/hour).

4. iFD-Stator® 2.0 for Easy Maintenance

- Stator wear is a common maintenance challenge in progressing cavity pumps. The NETZSCH iFD-Stator® 2.0 allows for quick replacement by unbolting a compressive shell, which releases radial and axial compression and makes it easy to slide in a new stator. This design reduces stator replacement time significantly, allowing maintenance staff to perform replacements faster and keep downtime to a minimum.

5. Customized Piping and Installation Configurations

- Proper installation and piping are essential for reliable operation. NETZSCH provides flexible piping options and modular installation configurations, which help minimize vibration and misalignment, reducing strain on pump components and extending service life. Shortened suction and discharge lines, long-radius elbows, and appropriately sized expansion joints all contribute to a more durable setup that minimizes pressure fluctuations.

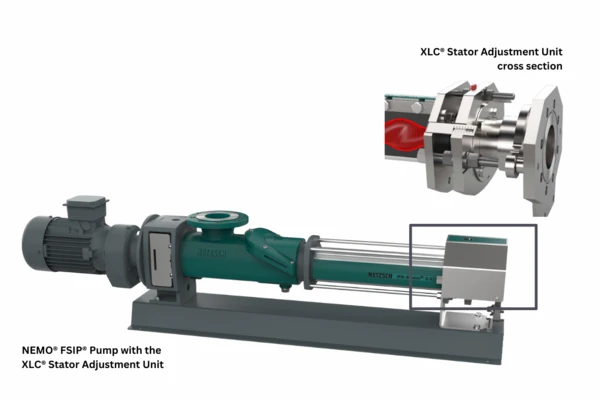

6. FSIP® (Full Service-in-Place) Design for Onsite Maintenance

- NETZSCH’s Full Service-in-Place (FSIP®) design allows maintenance teams to access critical pump components—such as the Rotorrotor,Rotors,rotorsrotor, stator, and mechanical seal—without disconnecting the pump from piping or electrical systems. This design minimizes the time required for repairs, making it an ideal solution for plants with limited space where quick access to pumps is essential.

Real World Impact: NETZSCH in Wastewater Applications

A municipal wastewater treatment facility recently installed NEMO® progressing cavity pumps with Flex Rod joints and iFD-Stator® technology. This setup allowed the facility to decrease both maintenance costs and wear. The Flex Rod joint eliminated joint lubrication needs, while the iFD-Stator® design allowed for rapid stator replacements, reducing downtime. This improved setup also reduced energy consumption due to its efficient direct-drive configuration

Comprehensive Support and After-Sales Service

NETZSCH Pumps & Systems India offers extensive support for municipal wastewater facilities, from initial installation guidance to after-sales service. The team assists with custom configurations and maintenance plans tailored to specific application requirements, ensuring NETZSCH pumps meet the demanding needs of municipal wastewater treatment.

Conclusion

For municipal wastewater treatment plants, NETZSCH offers robust and low-maintenance progressing cavity pump solutions that extend pump life and reduce operational costs. Through innovative design features like the iFD-Stator® 2.0, FSIP® maintenance access, and reliable joint technology, NETZSCH pumps are optimized for durability and ease of maintenance. By choosing NETZSCH pumps, wastewater treatment facilities can achieve efficient, reliable, and cost-effective operations, ensuring long-term performance and compliance with environmental standards.