NEMO® BT Immersible Pumps

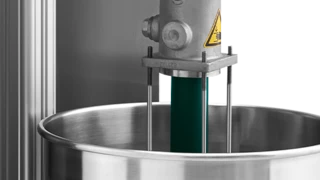

The NEMO® BT Immersible Pumps are vertically installed semi-submersible pumps, designed for efficient emptying and conveying of complex liquids from sumps, sedimentation tanks, pits, and similar vessels with liquid levels as deep as 12 mts. They excel in installations and applications where space is limited, and NPSH available is very low.

The Pumps are designed for several installation options and can be equipped with a bracket for crane suspension or mounted using sole plates for minimal vibration well within the tolerances. The pump design ensures continuous flow of sludge and has excellent wear resistant properties to handle solids content in the slurry. The pumps can be used for emptying and conveying the fluids over long distances due to is pressure handling capability. The Pump design with its low vibration ensures smooth operation with long service life.

Individual Consulting

Advantages

Efficient Fluid emptying at Low NPSH

Flexible Mounting

Long service life

NEMO® BT Immersible Pump Construction

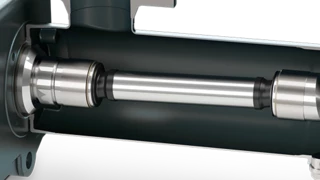

The NEMO® BT Immersible Vertical Pump features a robust, compact design with a directly flanged drive. The pump can be suspended using a bracket or installed with, mounting plates to suit the installation offering installation flexibility. The pump features the classic NEMO® progressing cavity pump design with 4 helical rotors and stators combination, ensuring precise, low-pulsation fluid transport while maintaining a constant flow rate, even with varying viscosities and solids content.

The shaft seal which is along the fluid flow ensures constant flushing of the seal faces ensuring long seal life. The length of the pump can be customized to meet the specific needs of the application, and installation allowing for optimal vertical immersion in vessels with varying depths. The pump is equipped with various drive options, including direct drives or geared motors, to match the application’s flow rate and pressure requirements. The suction housing is designed for effective fluid entry into the Rotorrotor,Rotors,rotorsrotor-stator system, the suction housing ensures the smooth transport of fluids, even under low NPSH conditions, minimizing the risk of cavitation.

The pump can be installed at immersion depth up to 12 m, an additional support guide is available to secure the pump to the bottom or to the wall near the bottom. The pump can be easily removed from the full tank as the guide units are self-centering and secure the pump suction without fixings. The pump can be specifically designed to operate within the API 676 standards and within its vibration tolerances. This ensures the long service life of the pump.

Comprehensive Service and Support

At NETZSCH, our commitment to your success extends well beyond the initial purchase of your NEMO® BO/SO Progressing Cavity Pump. We offer a complete range of aftermarket services to ensure your pump operates at peak efficiency and reliability throughout its lifecycle.

- Consultation: Our experts provide tailored advice to help you select the right pump configuration and optimize your processes.

- Spare Parts: We maintain a full inventory of genuine spare parts to minimize downtime and ensure optimal pump performance.

- Maintenance: Our routine and preventative services keep your pump running smoothly and prevent unexpected breakdowns.

- Repair: Swift and Efficient: Our prompt repair services ensure minimal disruption and a quick return to operation.

- Modernization: We offer modernization services to keep your pump system up-to-date with the latest technology and performance standards.

FAQs

Your contacts and companies at NETZSCH

Any specific questions? Contact us for help or fill in the contact form.