kaolin slurry

This Pump Will Reduce Your Kaolin Slurry Pumping Costs

How to pump kaolin slurry quickly and reliably directly from the train

“White gold” - the fact that this name for porcelain also applied to paper goes back a long time: Both are based on kaolin. This unique clay gives the materials luminous whiteness. Kaolin is used in paper production not only as a coating but also as a filler.

No matter how vital kaolin slurry is for paper production, the challenge of pumping it efficiently is equally huge. As a global specialist in handling complex media, NETZSCH Pumps & Systems offers an innovative pump solution for pumping kaolin slurry. We will show you how to make your paper production more efficient.

Individual Consulting

Paper Manufacturing

While porcelain and paper used to be called “white gold” and were considered a great treasure, today, paper companies worldwide are asking themselves how to make their production more efficient and thus withstand competitive pressure in the future. If you are faced with this question, we have the answer. As in many other areas, one factor is to increase the output of the kaolin slurry pumps and thus increase the production rate. For this reason, a paper company changed its production processes to delivery by train. In contrast to the transport by truck used until then, the rail route allowed larger quantities and, thus, cheaper procurement. However, the downtimes of the private railway company had to be kept as short as possible. At the same time, only a few square metres of space were available in the pump cellar; the previously used progressing cavity pumps could not have been accommodated there in the necessary number.

These are the challenges to overcome when pumping kaolin slurry

NEMO® Progressing Cavity Pumps are an indispensable part of paper manufacturing because of the gentle handling and low pulsation characteristics of these pumps. The NEMO® product line has the ideal pump for your applications, like handling filler materials such as calcium carbonate or kaolin, or for precision metering of chemicals such as polymers, wet strength agents or pigments.

How to pump kaolin slurry efficiently in confined spaces

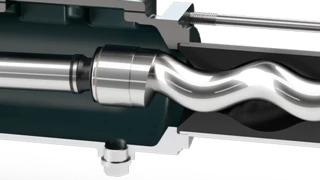

In close consultation with those responsible for the paper mill, the experts from NETZSCH found the right solution for pumping the kaolin slurry. The decision was finally made in favour of a TORNADO® T1-F rotary lobe pump, which is characterised by its small footprint and excellent flexibility, among other things. A total of five pumps were installed at the paper manufacturer's site, pumping around 70 m³ of kaolin slurry per hour with a viscosity of 100 to 500 mPas. Thanks to the choice of materials, the TORNADO® offers particularly long service lives. All pumps are made of a highly corrosion-resistant CrNiMo steel alloy. In addition, axially and radially abrasion-resistant wear protection plates are fitted, which you can easily replace if necessary. Furthermore, the multi-bladed lobes are made of resistant butadiene-sodium rubber with low shore hardness, which is especially suitable for abrasive products. However, in case cleaning or maintenance work becomes necessary, you can remove the front of the pump chamber in a few easy steps. This makes the entire pumping area easily accessible so that the individual components can be serviced or replaced without dismantling the housing from the system. This saves you time and, consequently, money during maintenance and servicing.

Smooth application, important to processes like color coating, is a requirement easily met with a “D” geometry Rotorrotor,Rotors,rotorsrotor. Just ask us; our engineering team will help you meet your requirements.

TORNADO® T1-F rotary lobe pump