19.03.2025

ATEX Pumps – Safe Conveying in Potentially Explosive Environments

Maximum safety and efficiency for demanding applications! Absolute safety is crucial in potentially explosive atmospheres, and ATEX pumps are specially designed for these requirements.

ATEX pumps ensure reliable and standard-compliant media pumping in sensitive industries such as chemicals, pharmaceuticals, oil and gas, and food production. Everything you need to know about ATEX pumps can be found here.

Customised Consulting

What does ATEX mean?

ATEX is the abbreviation for “ATmosphères EXplosibles” and refers to the European directives for explosion protection. These directives define the requirements for devices and protective systems used in potentially explosive atmospheres. ATEX comprises two primary directives of the European Union: the ATEX Product Directive (2014/34/EU), which regulates the requirements for equipment and defines the responsibilities of manufacturers, and the ATEX Operating Directive (1999/92/EC), describing the protective obligations of employers and the safety requirements for operations in potentially explosive atmospheres. ATEX applies to systems, machines and devices operating in environments with combustible gases, vapours, mists or dust.

What are ATEX pumps?

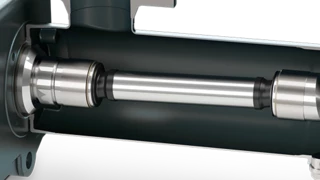

ATEX pumps are specially designed for safe use in potentially explosive atmospheres and comply with the ATEX Product Directive (2014/34/EU). Using explosion-proof motors, special materials, and constructive measures ensures the prevention of sparks or hot surfaces, which could be a source of ignition. These pumps are ideal for operation in environments with flammable gases, vapours, mists, or dust posing a potential explosion hazard. They are made of high-quality, antistatic, and chemically resistant materials, ensuring a wide range of media is pumped safely. Depending on the zone classification, ATEX pumps are equipped with special motors, seals and grounding concepts to eliminate electrical or mechanical ignition sources. Thanks to these features, ATEX pumps ensure safe and reliable operation in potentially explosive atmospheres and contribute to the protection of people and the environment.

Where are ATEX pumps used?

In many industries, potentially explosive zones require special pump solutions. ATEX pumps are used, among others, in the following areas:

- Chemical industry: Pumping of flammable liquids and chemicals

- Oil and gas industry: Safe handling of flammable media

- Pharmaceutical production: Process safety with sensitive substances

- Food and beverage industry: Explosion-proof pumping of products containing alcohol

- Paint and varnish production: Safe transport of solvents and coating materials

Advantages of NETZSCH ATEX pumps

Our ATEX-certified pumps offer numerous advantages and guarantee the highest level of safety in accordance with the ATEX Directives 2014/34/EU. They are specially designed for demanding media and ensure reliable pumping, even under difficult operating conditions. Thanks to individual customisation options, our pumps can be precisely tailored to your requirements, providing a solution perfectly suited to your processes. In addition to their high efficiency, which is characterised by low energy consumption and durable components, our ATEX pumps are easy to maintain. Minimised downtime and simple servicing enable you to operate economically and maximise system availability. With our solutions, we ensure your processes are not only efficient but also as safe as possible – even in potentially explosive atmospheres.

Why NETZSCH for ATEX Pumps?

As a global specialist in handling complex media, NETZSCH Pumps & Systems can draw on more than 70 years of experience in the pump sector. Our NEMO® progressing cavity pumps, TORNADO® rotary lobe pumps, NOTOS® multi screw pumps and PERIPRO® peristaltic pumps are available in ATEX-certified versions to ensure your process reliability. However, we offer you not only high-quality products but also comprehensive advice and service.

Our expertise in ATEX-compliant pump systems ensures you always receive a reliable and standard-compliant solution. We promise you Proven Excellence – outstanding performance in all areas. Even the most demanding media are no match for our product portfolio.