19.03.2021

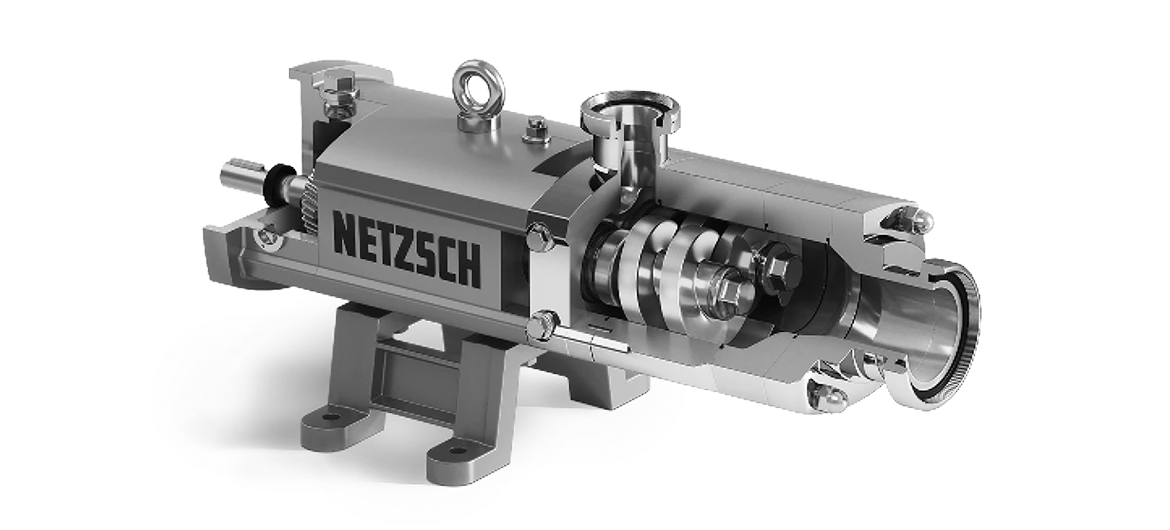

NETZSCH Memperluas Portofolio Dengan Pompa Multi Sekrup untuk Aplikasi Higienis

"Dengan pompa ulir higienis NOTOS® kami yang mudah dibersihkan dan dirawat, Anda akan mengirimkan produk Anda bebas dari kontaminasi", kata Rainer Gozzer, Manajer Lapangan Bisnis Makanan & Farmasi di NETZSCH di Waldkraiburg tentang penambahan portofolio produk pompa perpindahan positif.

In addition to the NOTOS® 2NSH hygienic twin screw pump in conventional design with optional heating jacket, we offer the NOTOS® 2NSH in a convenient FSIP® (Full-Service-In-Place) design as well as a barrel emptying system for your application. A combination of the highest product safety paired with the usual high NETZSCH quality. This will optimally equip you for any challenge in the hygienic area.

Pembersihan bebas kontaminasi dan bebas residu

Whether it's orange juice concentrate, fruit yoghurt or shampoo, all these products have one thing in common: Contamination turns the medium unusable and results in high reject costs. Therefore, we have made it our duty to design a pump for you in which any kind of contamination by operating media or wear-related abrasion can be ruled out. This is ensured by contactless conveying, in which the pumping elements do not come into contact with each other. The NOTOS® 2NSH can also be cleaned without leaving any residues using the CIP process (Cleaning-In-Place) and afterwards sterilized using the SIP process (Sterilization-in-Place). The system can be cleaned or sterilized in a circular or continuous process without prior disassembly. The combination of contactless conveying elements and the flange-mounted gearless three-phase motor enables a high pump speed. Thus, the flow speed of 1.5 m/s, which is decisive for the CIP process, is ensured. Residue-free cleaning is facilitated by the dead-space-free design of the pump. In addition, the all-metal construction is insensitive to high temperatures, which are essential for the SIP process.

Pengalaman bertahun-tahun dengan pompa multi-sekrup

Pompa ulir kembar higienis yang baru didasarkan pada model 2NS dari seri NOTOS®, yang telah terbukti selama beberapa dekade. Seri ini memiliki karakteristik laju aliran dan tekanan yang tinggi namun hanya membutuhkan sedikit ruang. "Ketika pompa beroperasi, ruang-ruang dibentuk dengan menggunakan dua sekrup yang saling bertautan dan berputar berlawanan yang dikombinasikan dengan rumah pompa. Di dalam ruang-ruang ini, media yang dipompa terus menerus dipindahkan secara aksial dari saluran masuk pompa ke sisi pembuangan", Gozzer menjelaskan. NOTOS ® 2NSH memompa media dengan laju aliran hingga 200 m³/jam. Tekanan pengiriman hingga 16 bar dapat dicapai.

Satu pompa, tiga versi dan keuntungan yang tak terhitung jumlahnya

Konsultasi dapat disesuaikan

The FSIP® version of the twin screw pump enables you to perform simple service and quick maintenance without removing the pump from the system or pipeline. When used in wear-intensive applications, where increased service and maintenance is to be expected, you save considerable capacities and thus costs. Furthermore, a conventional version is also available. It can be optionally equipped with a heating or cooling jacket. The jacket enables you to pump the medium at constant temperatures. This is an indispensable addition for applications where the pumped medium tends to harden or where temperature regulation is required. The third variant is the barrel emptying system: It guarantees you almost complete emptying in compliance with the strictest hygienic standards and safety regulations. With the new NOTOS®hygienic pump, you can efficiently convey even the most demanding media with absolute process reliability.