25.02.2021

Rotary Lobe Pump Advantages: High Power, Compact Design and Easy Service

Safe processes require, above all, reliable equipment. The question often arises about the right technology and, associated with this, the right pump type. The rotary lobe pump technology offers a wide range of applications and combines numerous advantages.

Rotary lobe pumps are self-priming, valveless, rotating positive displacement pumps. Due to their compact design, high power density and operational reliability, they are often used for continuous and gentle conveying as well as dosing in proportion to rotational speed. As a result, rotary lobe pumps can easily handle various media, especially demanding media with special pumping characteristics. These include, for example, industrial wastewater, fatty acids or ceramic slurry.

Operating principle of a rotary lobe pump: The Rotorrotor,Rotors,rotorsrotor pair's rotation creates a negative pressure on the suction side, whereby the medium is sucked in and then conveyed along with the pump housing to the discharge side. Advantages of a rotary lobe pump:

High flexibility for a wide range of media

Konsultasi dapat disesuaikan

Rotary lobe pumps can convey media with a wide range of different properties. These include low and high viscosity, solids-loaden, solids-free, shear-sensitive, abrasive, non-lubricating and lubricating media. Also, fluctuating solids content is no problem for the pump.

Low risk of media entrapment and compaction

A large, free ball passage and the low speed, compared to other technologies, make the rotary lobe pump extremely resistant to any media entrapment, compaction and foreign objects.

Change of rotation

Rotary lobe pumps are self-priming, i.e. they can build up pressure to such a high level without external help that the medium can be sucked in independently. Their usually symmetrical design allows a reversal of the direction of rotation and thus of the direction of delivery. This is an advantage, especially concerning emptying. No further modification is needed to switch the pump from filling to emptying. Only the pumping direction has to be changed.

Efisiensi tinggi dengan biaya siklus hidup yang rendah

Compared to other positive displacement pumps, the rotary lobe pump has very high efficiency. This results in significantly lower energy consumption. A significant advantage, as energy costs are a large part of the life cycle costs. The high flexibility with regard to a wide variety of pumped media can further reduce the costs: In some applications, the rotary lobe pump can be used for several production steps. This results in reduced costs for spare parts storage as well as lower training costs.

Easy maintenance and compact design

Maintenance and service of the rotary lobe pump can be quickly done by removing the pump cover. Compared to the progressing cavity pump, this saves additional assembly time to remove the piping system. The small dimensions reduce the costs for the enclosed space in the system and thus offer more room for installing the unit in the system.

Lembut, denyut rendah, dan pengantaran yang konstan

The technology of the rotary lobe pump is characterized by continuous, low-pulsation and constant conveying. The conveying capacity can be regulated in proportion to the speed, so that exact dosing is possible. Transferring by so-called conveying chambers is exceptionally gentle on the product and thus enables the use in almost any application. This is a significant advantage, especially for demanding media.

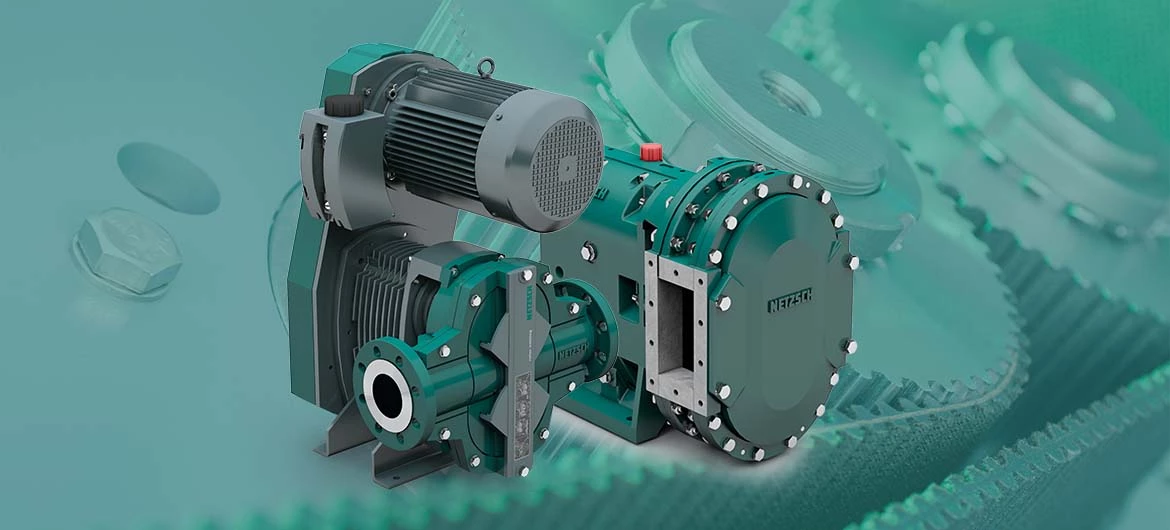

Seorang multi-talenta yang sesungguhnya: The Pompa rotary lobe TORNADO®

Pompa lobus putar benar-benar dapat disebut "serba bisa" di bidang pompa perpindahan positif. NETZSCH Pumps & Systems telah menjadikannya sebagai bisnis untuk mengembangkan lebih lanjut dan menyempurnakan berbagai keunggulan teknologi pompa rotary lobe, yang disesuaikan dengan kebutuhan pelanggan individu: Pompa lobus putarTORNADO® T2 - Kombinasi teknologi pompa yang telah terbukti yang dipasangkan dengan teknologi terbaru dalam bidang teknik.

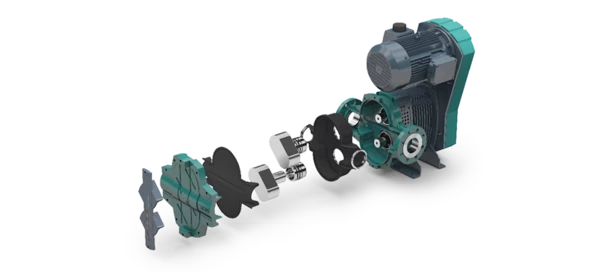

Pembalikan material yang cerdas antara komponen statis dan dinamis memastikan lebih sedikit tekanan pada bagian elastomer karena deformasi plastis. Selama gerakan rotasi lobus, hanya karet dan logam yang bersentuhan. Kontak yang tidak menguntungkan dan intensif keausan antara bagian-bagian karet dihilangkan. Karena ekspansi yang kecil dari lobus logam-karet dan sisipan karet, pompa juga dapat digunakan pada suhu operasi yang bervariasi tanpa mengurangi masa pakai dan efisiensi.

Sabuk roda gigi bergigi dua sisi, yang merealisasikan penggerak dan sinkronisasi, tidak memerlukan pelumasan seperti roda gigi sinkron konvensional. Ini sepenuhnya menghilangkan kehilangan oli dan penggantian oli. Desain sinkronisasi yang sederhana memastikan waktu servis yang lebih singkat saat mengganti sabuk roda gigi bergigi.

Dibandingkan dengan pompa lobus putar konvensional, servis TORNADO® T2 dapat dilakukan dalam waktu kurang dari separuh waktu. Kata kunci: "Servis Penuh di Tempat." Karena bagian depan yang lengkap dapat dibuka, Anda memiliki akses yang cepat dan mudah ke dalam ruang pompa hingga ke sambungan flensa. Selain itu, desain yang sederhana menghilangkan kebutuhan akan alat khusus yang mahal. Inspeksi, pembersihan, atau bahkan penggantian suku cadang yang aus menjadi sangat mudah dalam waktu singkat.

Pompa digerakkan dan juga disinkronkan oleh roda gigi sinkronisasi sabuk. Pemisahan spasial ruang pompa dari mekanisme sinkronisasi memastikan keandalan operasional yang lengkap dengan setiap pompa lobus putar dari NETZSCH. Dengan menggunakan penggerak sabuk, pompa benar-benar bebas oli, dan kebocoran oli roda gigi dapat dihilangkan.

NETZSCH Pumps & Systems memiliki pengalaman bertahun-tahun dalam pembuatan pompa lobus putar. Dikombinasikan dengan penelitian dan pengembangan yang berkelanjutan, NETZSCH telah mampu memposisikan dirinya sebagai ahli mutlak di pasar dan berhasil merancang aplikasi yang paling beragam, sesulit apa pun.