09.06.2025

Battery Pumps: Efficient Pumping for Demanding Applications

Precision and reliability in battery production! The highest precision and process reliability are required in battery production. Specialised pump systems are particularly important when pumping highly viscous, abrasive, or sensitive media.

NETZSCH Pumps & Systems, the global specialist in handling complex media, offers customised solutions that ensure precise dosing and gentle pumping for maximum efficiency and product quality. The most important facts about battery pumps at a glance:

- Precision and reliability

- Versatile areas of application

- Challenges in battery production

- Innovative pump technologies

- Your partner for maximum efficiency

Why are battery pumps essential?

Customised Consulting

The precise handling of raw materials is crucial to producing lithium-ion batteries and other energy storage devices. Cathode and anode pastes, electrolytes and other sensitive materials must be conveyed without contamination or loss. Our battery pumps are specially designed to meet these requirements and ensure consistent product quality.

Typical applications battery pumps are used

The requirements for pump systems in battery production are as diverse as the processes themselves. From raw material extraction to manufacturing and recycling: Pumps are needed in all process steps. High-performance pumps convey raw materials such as lithium, nickel, and manganese safely and efficiently, while electrolyte slurries are reliably transported and processed by wet grinding and de-clumping. When mixing electrolytes, precise metering pumps ensure a homogeneous composition, and in the coating process, pulsation-free progressing cavity pumps guarantee an even layer thickness on the electrodes. In addition, pumps support recycling old batteries by enabling the efficient reprocessing of valuable raw materials. With customised solutions, NETZSCH contributes to the efficiency and sustainability of battery production.

Challenges for battery pumps

Battery production places high demands on the pump technology used. Precise metering is essential to ensure the quality of the battery cells and to guarantee exact quantity delivery. At the same time, battery pumps must enable gentle delivery to avoid damaging highly sensitive materials by shear forces or altering their chemical composition. Since aggressive substances such as electrolytes are often used in battery production, the pump materials must be highly resistant to chemicals. In addition, avoiding contamination plays a crucial roller. Media must be pumped safely and without contamination.

Our pump solutions for battery production

As a global specialist in handling complex media, we offer innovative solutions worldwide for every step of the battery manufacturing process. We can draw on a broad portfolio of pump technologies. „Our specifically designed pumps for the battery sector enable you to gently convey all the required liquids, including electrode slurries, without pulsation and dose them with extremely high precision whilst fulfilling the most stringent safety and environmental regulations”, Thomas Böhme, Global Business Development Battery.

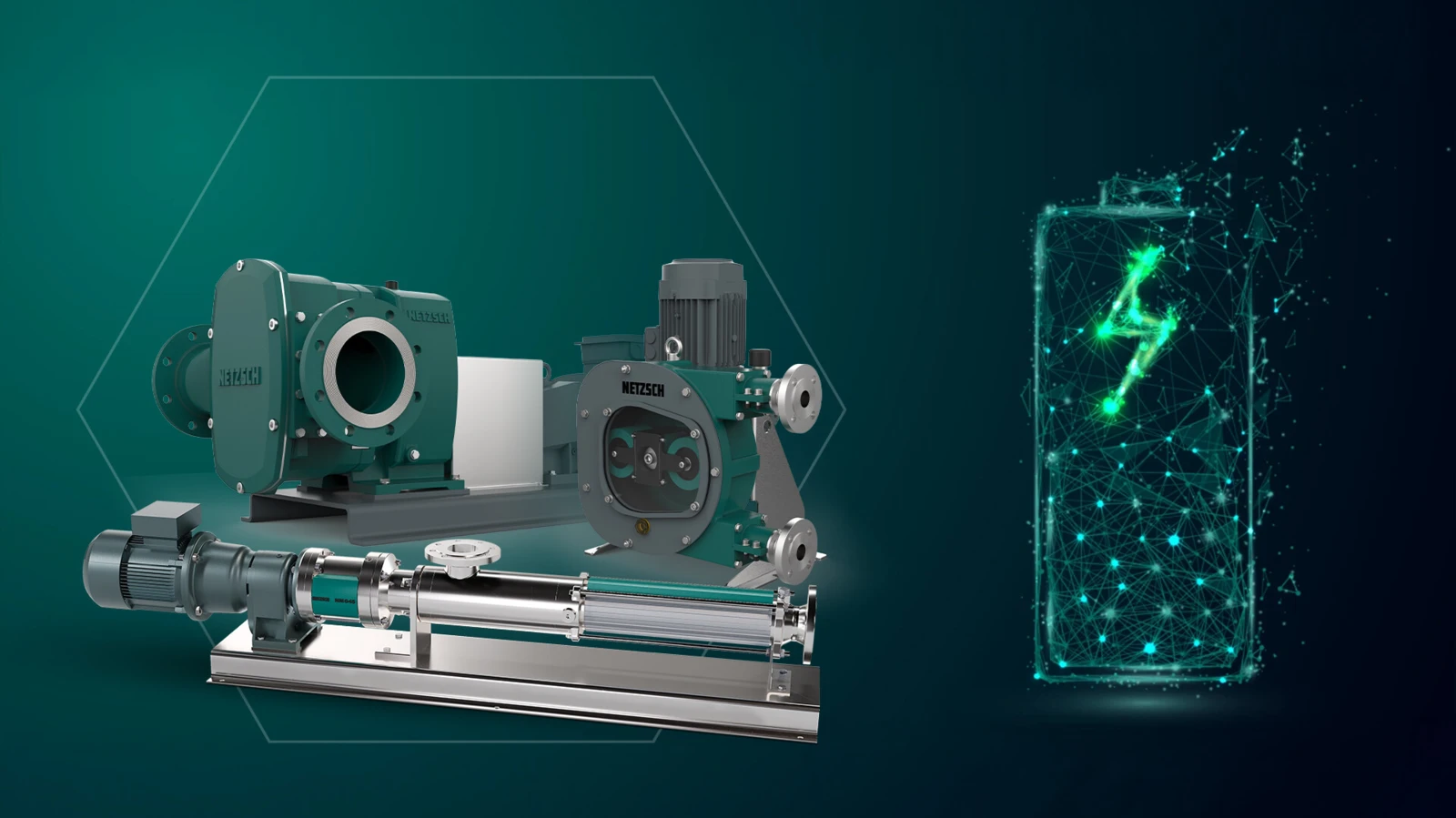

For example, NEMO® progressing cavity pumps are ideally suited for highly viscous and abrasive media, enabling pulsation-free conveyance and the highest degree of dosing precision. TORNADO® rotary lobe pumps impress with compact design and high pumping capacity while ensuring gentle media handling. NOTOS® multi screw pumps are ideally designed for pumping various types of rock and are exceptionally wear-resistant. In addition, PERIPRO® peristaltic pumps can be coupled in any position, making them ideal for applications where pastelike or sensitive substances must be pumped without contamination. With this wide variety of pump systems, NETZSCH ensures every requirement in battery production is met efficiently and reliably.

Your partner for efficient battery pumps

With more than seven decades of experience, NETZSCH develops, produces and distributes innovative solutions for industrial applications. Our battery pumps help to optimise your battery manufacturing processes and meet the highest quality standards. Rely on proven technology, excellent advice and customised solutions – for maximum efficiency and safety in your production.

Contact us and let our experts advise you on your pump solution. Together with you, we will find the pump system optimally tailored to your requirements.