Pumps for conveying sugar syrup

Sugar Syrup Transfer Pump

Learn how NETZSCH PERIPRO Peristaltic Hose Pump efficiently solved the sugar crystallization challenge in the confectionery industry

One of the largest manufacturers and distributors of candies and chewing gums in Chennai, India is known for their high-quality products in the confectionery industry. This customer being in the confectionary industry handles sugar syrups in their process.

As a global specialist in complex fluid management, NETZSCH Pumps & Systems India provided an optimal solution. We will show you how sugar syrup is transferred in the confectionery industry gently preventing crystallization and reducing the maintenance/downtime costs.

Individual Consulting

Challenges when conveying sugar syrup

During a consultative visit to the plant for a pump requirement, our client expressed their concern over the current pump i.e., Gear Pump that was used for conveying sugar syrup. The major concerns were the frequent jamming, mechanical seal damage, and increased starting torque.

When the sugar syrup is transferred through the gear pump, the crystals in the suspension are entrapped between the gears increasing the friction between the gear teeth and the pump casing. This results in temperature raise which can cause wear to the pump elements and if overheated, seizes the pump too.

The temperature rise also results in the demand for high torque to deliver the required output resulting in high power consumption. Also, Cleaning the sticky sugar syrup from the gears required long hours which increased the downtime of the pump affecting the production efficiency.

The inappropriate selection of the pumps which have a high number of contact points is one of the primary reasons for the frequent jamming of the pump.

The ideal solution for transferring sugar syrup

After a detailed understanding of the challenge and considering the sugar syrup's nature, the pump has to be operated at low speed creating a gentle pumping action preventing crystallization of sugar syrup and minimizing the shear.

If the contact parts with media are few, it eases the cleaning process and also produces no to low friction on the parts which reduces the maintenance, operational costs and reduces the downtime.

The absence of valves, seals, and internal components like gears minimizes the risk of clogging, which is critical when handling sticky fluids like sugar syrup that can accumulate on surfaces.

Optimal Pumping Solution for handling shear-sensitive & abrasive fluids like sugar syrup

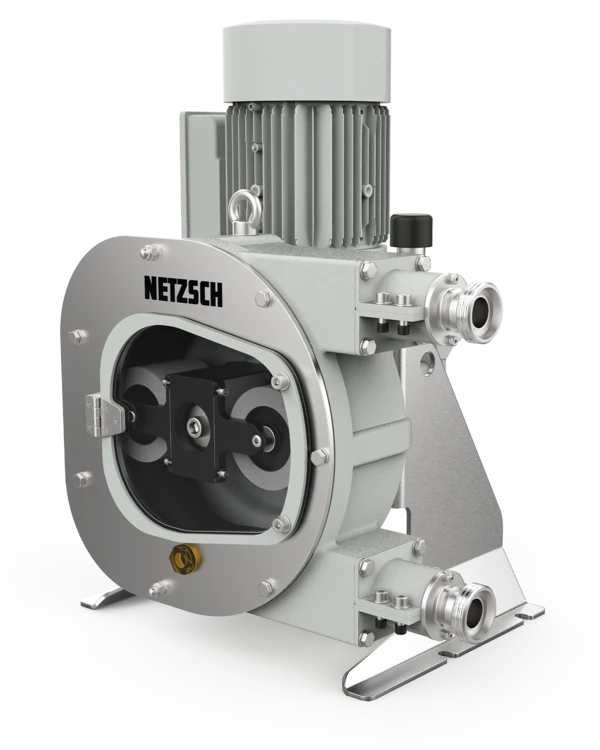

The PERIPRO® Peristaltic Hose Pumps are an excellent solution for handling shear-sensitive and abrasive fluids like sugar syrup. They are capable of handling solids content of up to 70 % with high suction capacity and minimal maintenance at the same time. Its robustness, reliability, and strength guarantee a gentle and steady pumping of the fluids. It is designed to operate continuously and withstand varying temperatures and the abrasiveness of fluids.

The ease of maintenance of our peristaltic pumps allows you to carry out maintenance work without special tools or extensive expertise. Simplifying and optimizing the cleaning processes with our CIP-capable PERIPRO® peristaltic hose pump is a feather in the hat saving time and reducing the risk of contamination.

Our hose complies with the strictest hygiene standards of the FDA, meeting the expectations of food industries. The easy changing of the hose allows the customer to use one pump for multiple fluids only by changing the hose during the use of that fluid.

With customer satisfaction as our top priority, our service offering for the peristaltic pump extends to making the best use of it.

PERIPRO® Peristaltic Hose Pump

- Medium: Sugar Syrup

- Capacity: 600 kg/h

- Pressure: 3,4 bar

- Temperature: 45 °C