The NEMO® BH Hygienic Progressing Cavity Pump is ideal for sanitary applications to convey highly viscous, shear sensitive, abrasive, and solids-containing media in food, beverage, pharmaceutical, cosmetic, and certain chemical/biochemical industries.

This pump provides continuous, low-pulsation, and low-shear, liquid conveyance, making it ideal for critical processes in the food, cosmetics, pharmaceutical, chemical, and biochemical industries.

This progressing cavity pump is best suited in applications where high sanitary standards is critical. Its critical design features include FDA Certified Materials, compliant mechanical seals, and liquid contact areas that are free of dead space. The primary area of application is to handle shear-sensitive, and thin to viscous media, with or without solids. The NEMO® BH Pump guarantees hygienic conveying and high dosing accuracy, with less than one percent deviations, ensuring precise and reliable performance.

The hygienic design of the pump components is suited for CIP (Clean-in-Place) and SIP processes. It meets stringent regulatory standards for cleanliness and safety in the food processing industry.

NEMO® BH Hygienic Pump Meets Numerous Hygiene Guidelines

NEMO® pumps are designed, manufactured, and tested to comply with the following standards:

- FDA Compliance: Meets the stringent requirements of the Food and Drug Administration (FDA).

- EU VO 1935/2004 Compliance: It conforms to the European Union regulations for materials intended to come into contact with food.

- 3-A Sanitary Standard: Complies with the 3-A Sanitary Standards of the USA, guaranteeing high hygiene levels.

Individual Consulting

Advantages of NEMO® BH Hygienic Pump

Gentle Conveyance in Sanitary applications

Compact Design and Flexible Installation

The Pump design allows the capability to have reversible flow with the same hydraulic performance

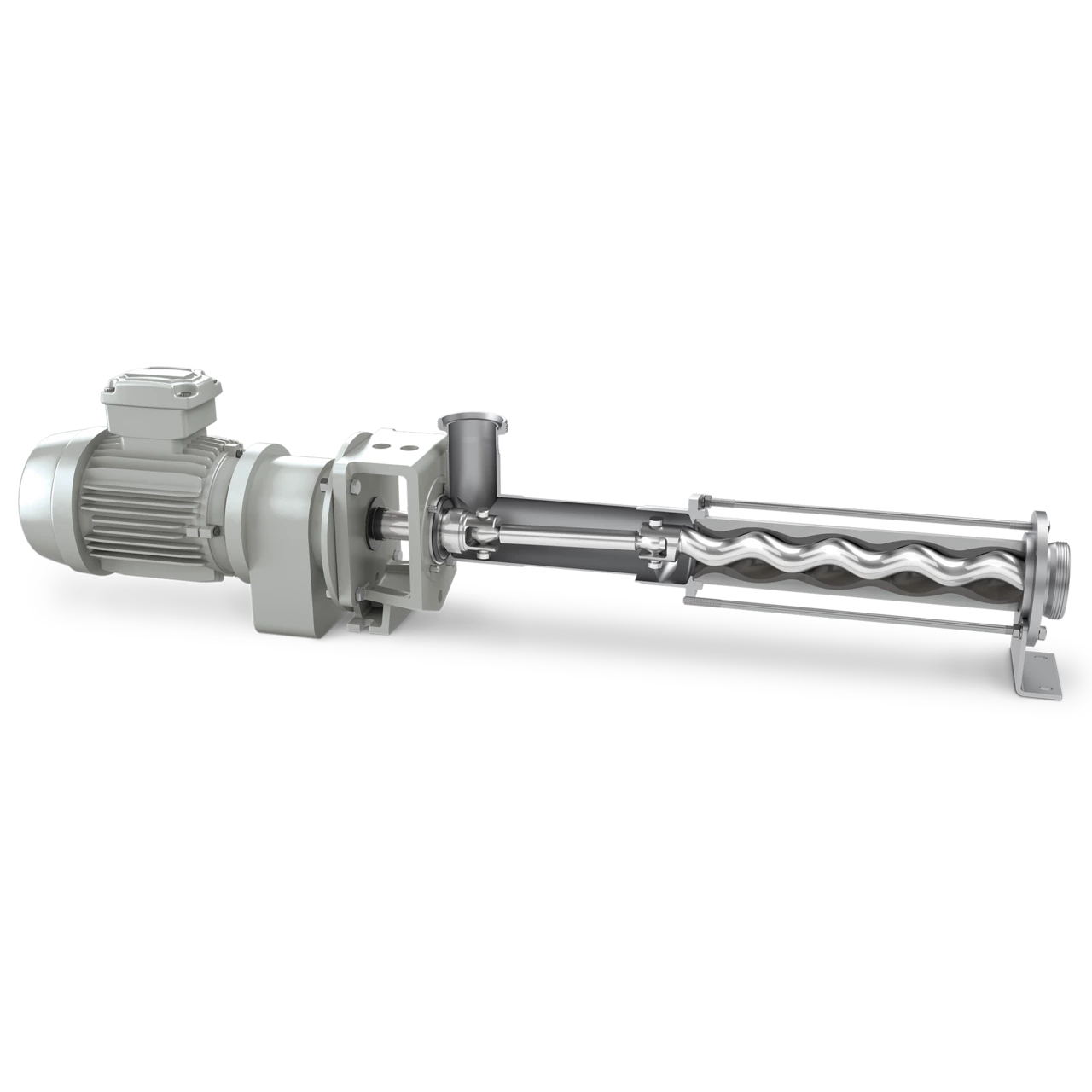

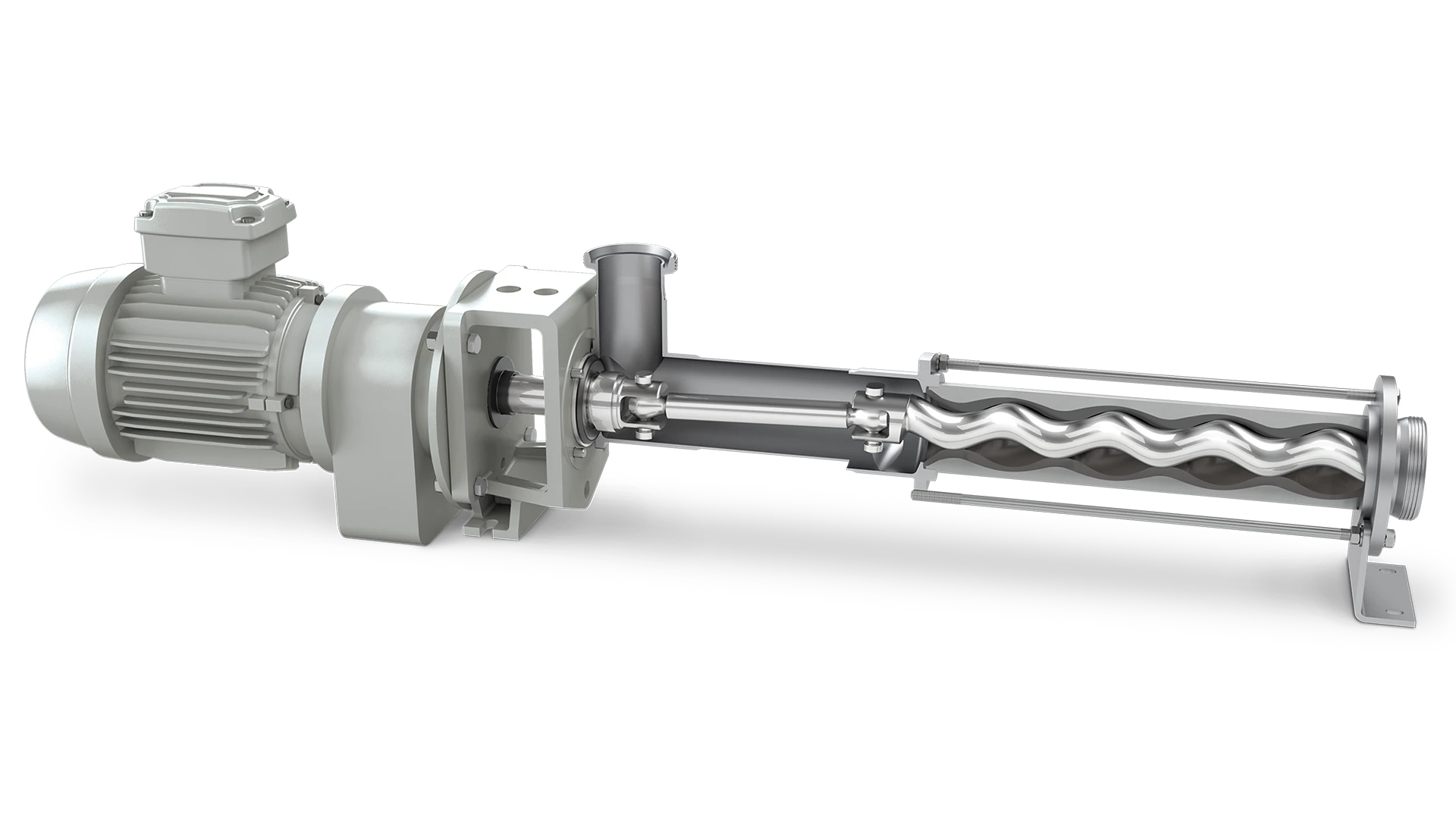

NEMO® BH Hygienic Pump Construction

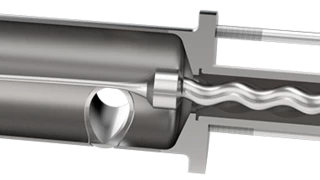

The NEMO® BH Hygienic Progressing Cavity Pump features a compact design with a directly flanged drive and open hygienic pin joints. It has no dead spaces or crevices that could cause fluid deposits, ensuring excellent cleanability.

The pump seals comply with hygienic industry standards. The pumping elements - the Rotorrotor,Rotors,rotorsrotor is made with compliant materials and polished for a smooth finish for no fluid deposits, and the elastomer part in the stator is compliant with FDA Standards for sanitary applications.

The suction and discharge housings are of specific design to ensure smooth flow and avoid settling of the liquid medium in any dead spots or crevices. The surfaces are polished to meet the application demand. The end connections come with options to provide hygienic connections. The pump is an equipped construction with CIP-able design.

The shaft seal is in the flow path of the liquid and is wetted and lubricated with the process liquid. The pump is equipped with food industry-compliant mechanical seals for reliability and safety. The design of the pump is suited for reverse flow. The pumps are ideal for viscous, shear-sensitive liquids and those with solids, ensuring high hygiene standards.

A pump stator with reduced elastomer wall thickness allows for a wide operating temperature range. The stator inlet has a conical shape for improved feed into the pumping elements.

A thermal stator protector (STP-2 or STP-D) guards against overheating and dry running. FDA-certified connecting shaft seals are used for sanitary applications. All product-contact surfaces are smoothly polished to prevent medium deposits and facilitate cleaning.

The pump can also include a heating jacket over the stator and pump housing to maintain the media temperature sensitive to temperature changes.

Comprehensive Service and Support

At NETZSCH, our commitment to your success extends well beyond the initial purchase of your NEMO® BH Hygienic Pump. We offer a complete range of aftermarket services to ensure your pump operates at peak efficiency and reliability throughout its lifecycle.

- Consultation: Our experts provide tailored advice to help you select the right pump configuration and optimize your processes.

- Spare Parts: We maintain a full inventory of genuine spare parts to minimize downtime and ensure optimal pump performance.

- Maintenance: Our routine and preventative services keep your pump running smoothly and prevent unexpected breakdowns.

- Repair: Swift and Efficient: Our prompt repair services ensure minimal disruption and a quick return to operation.

- Modernization: We offer modernization services to keep your pump system up-to-date with the latest technology and performance standards.

FAQs

Contact Us for Expert Hygienic Pump Solutions

While faced with needs or challenges in conveying complex fluids in sanitary applications we can offer the right design of NEMO® BH Hygienic Pump. Our team of experts is here to provide personalized advice and solutions tailored to your specific needs.

Contact us and experience the precision, reliability, and efficiency of the NEMO® BH - Hygienic Pump!

Your contacts and companies at NETZSCH

Any specific questions? Contact us for help or fill in the contact form.