Rotary Lobe Pumps for Biogas digestate transfer

Seamless Operation of TORNADO® Rotary Lobe Pump in Biogas Plants

In modern biogas production, ensuring continuous operation is critical to meet the energy demands and maintaining efficiency. One of the leading pioneers in biogas sector develop technologies to generate alternative source of energy for electricity, heat, or as vehicle fuel from organic waste, while the by-products, such as digestate, are used fertilizers.

Explore how NETZSCH TORNADO® Rotary Lobe Pump ensures seamless operation and efficiency in biogas plants

Individual Consulting

Nature of Biogas Slurries

Biogas is produced by the anaerobic digestion of organic materials such as agricultural waste, sewage sludge, and food waste. This process occurs in a biogas digester, where microorganisms break down the organic matter in the absence of oxygen, producing a biogas mix of methane and carbon dioxide.

Every day, the plant processes tonnes of agricultural residues, manure, food waste, and sewage sludge which often contain a mix of solids, liquids, and gases, presenting several challenges.

Challenges

The slurries are often thick and fibrous making them difficult to pump, leading to clog in ordinary pumps, thus resulting in unplanned downtime. Biogas plants often experience fluctuations in material flow, requiring pumps that can adapt without compromising performance.

Taking into consideration the nature of fluid at each stage, the pumps for these applications needs to be carefully selected.

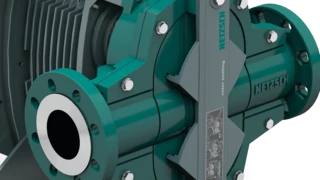

TORNADO® Rotary Lobe Pump for sludges/slurries

NETZSCH proposed rotary lobe pumps for digester transfer application that involved continuous pumping of thick slurries from digesters into digestate and transferring digestate after digestion for post-processing or fertilizer application. These fluids were low viscous and contained compressible soft solids that could be smoothly pumped with rotary lobe pumps.

Our TORNADO® pumps are designed to ensure smooth flow and seamless operation to meet the requirements of biogas plants.

- Robust Construction: Designed to handle the abrasive and corrosive nature of biogas slurries.

- Reliable Performance: Adapts seamlessly to feedstock changes, ensuring optimal flow without interruptions.

- Low-Shear Pumping: Preserves anaerobic bacteria, essential for maximizing biogas production, by transferring slurries with minimal shear.

- Self-Priming and Dry-Run Tolerant: Ensures smooth startup and operation, even during inconsistent flow, without risk of damage from dry runs.

- Compact Design: Fits perfectly in tight plant layouts, saving valuable space.

- Full Service in Place: The design allows for quick and easy access to the pump chamber that reduces service and maintenance downtime ensuring that the pump can be serviced without dismantling the pump or disconnect the pipework.

- Minimal Maintenance: Quick and easy maintenance, with no special tools needed, ensuring maximum uptime and reduced costs.

- Fibrous Material Management: Non-clogging Rotorrotor,Rotors,rotorsrotor design manages fibrous slurries like crop residues or plant matter effectively, preventing blockages.

The NETZSCH TORNADO® Pumps are a critical asset in biogas plants, offering unmatched reliability and efficiency.

TORNADO® Rotary Lobe Pump

- Medium: Biogas Slurry

- Temperature: Up to 80 °C

- Capacity: Up to 70 m³/h

- Pressure: Up to 48 bar