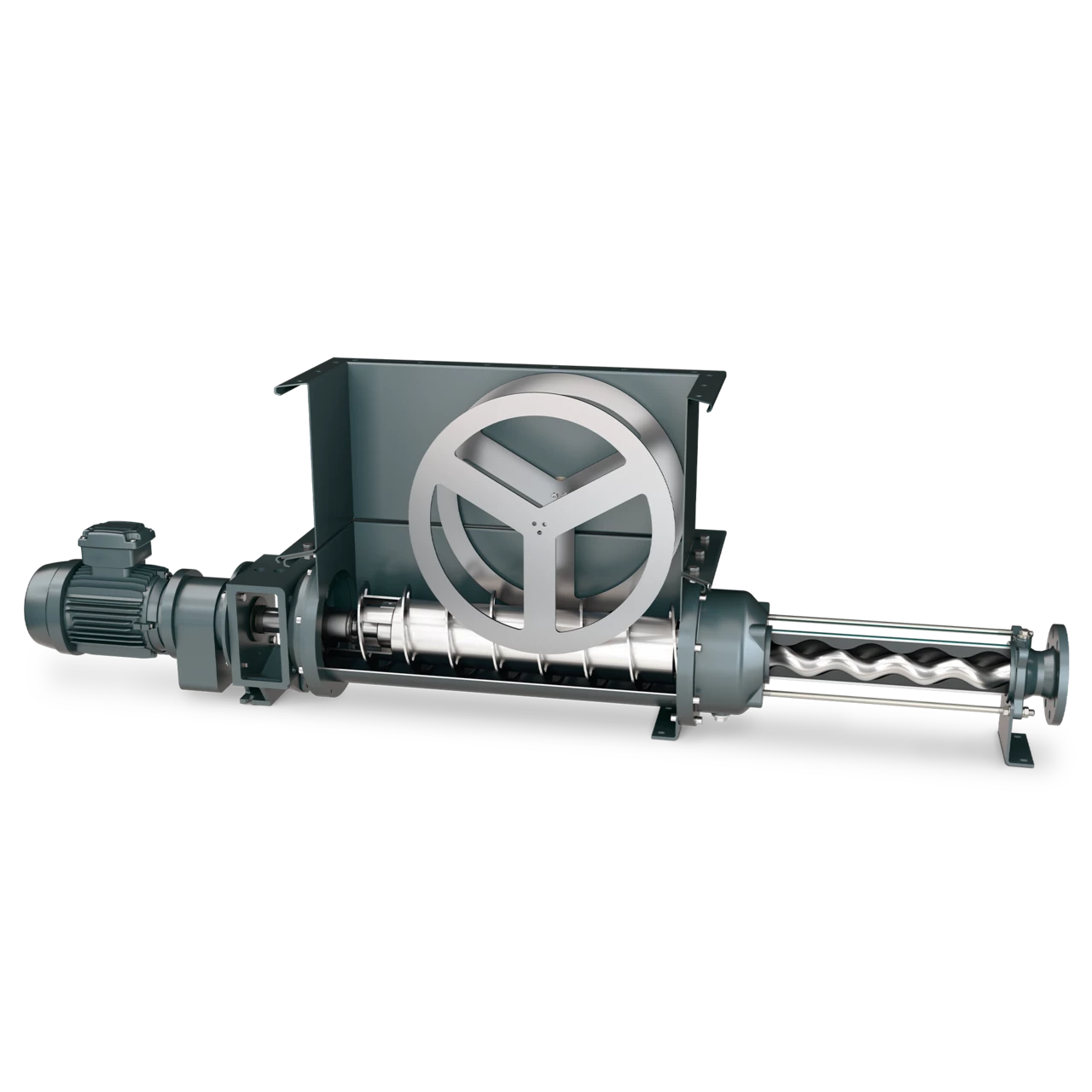

The NEMO® BF hopper-design progressing cavity pump with aBP-Module® is specifically engineered to handle highly viscous and crumbly substances that tend to bridge. The aBP-Module® (Asynchronous Bridge Preventing) can be additionally mounted on the pump to prevent media bridging in the hopper and ensure continuous feeding into the conveying elements.

This pump can be deployed across various industries to transfer high viscous and crumbly media efficiently across various industries.

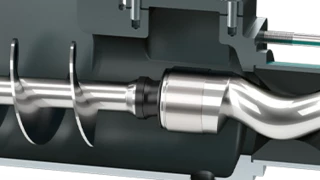

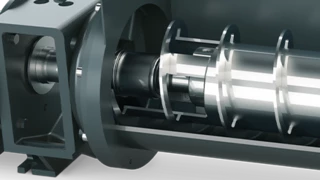

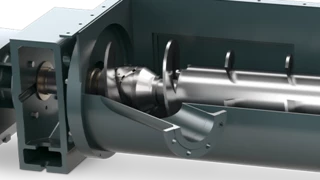

The pump housing features an enlarged, rectangular feed hopper and a conical force-feed chamber for optimal product feed into the conveying elements like NEMO® BF Hopper Pump. Additionally, it incorporates a special coupling rod with a patented, positioned conveying screw. The pump is further enhanced by the aBP-Module® consisting of a top shaft with two internal spoke wheels—to prevent bridging and ensure efficient operation.

NEMO® BF hopper shaped pump prevents bridging

These create “moving shaft walls” which exert a shearing effect on the medium. This reliably prevents bridge formation in the pump shaft. This also ensures the smooth conveying of solid-loaden, shear-sensitive, abrasive, adhesive, thixotropic or dilatant as well as lubricating and non-lubricating materials that have a tendency to bridge. The NEMO® is particularly compact and economical in block construction with flanged drive.

Individual Consulting

Advantages of NEMO® BF Hopper Design Pump With aBP-Module®

Uninterrupted Feeding of Viscous Medium

Service

Engineered Design

NEMO® BF Hopper Design Pump With aBP-Module® Construction

NEMO® BF Hopper Progressing Cavity Pump with aBP® module is offered with a suction housing, enlarged rectangular hopper design along the conveying screw, and conical force-feed chamber.

The aBP® Module is mounted on the suction housing. This module creates "moving shaft walls" which exert a shearing effect on the medium. This reliably prevents bridge formation in the pump suction. This also ensures the smooth conveying of solid-loaden, shear-sensitive, abrasive, adhesive, thixotropic or dilatant as well as lubricating and non-lubricating materials that have a tendency to be sticky and bridge.

The NEMO® BF hopper pump with aBP Module is particularly compact and economical in block construction with a flanged drive. The drive is connected with a patented horizontally positioned coupling rod with a feeding screw for optimal feed into the conveying elements.

The pump housing can be designed with materials in steel, stainless steel, or any other exotic materials and can also be coated for wear protection and chemical resistance. The stator is vulcanized into the housing with sealing on both sides in a variety of elastomers. The stator inlet is designed with a hopper-shaped opening for improved feed of the product into the conveying chamber.

Shaft seals are standard seals with single-acting, bi-directional, and wear-resistant. Upon request, with single- or double-acting mechanical seals of varied designs and from various manufacturers, cartridge and special seals as well as packed glands are available based on the complexity of the application.

The NEMO® BF pump with aBP® Module construction is designed to convey high viscous and crumbly media reliability, and for ease of maintenance, making it a preferred choice for a wide range of industrial applications.

Comprehensive Service and Support

At NETZSCH, our commitment to your success extends well beyond the initial purchase of your NEMO® BF Hopper aBP® Module Progressing Cavity Pump. We offer a complete range of aftermarket services to ensure your pump operates at peak efficiency and reliability throughout its lifecycle.

- Consultation: Our experts provide tailored advice to help you select the right pump configuration and optimize your processes.

- Spare Parts: We maintain a full inventory of genuine spare parts to minimize downtime and ensure optimal pump performance.

- Maintenance: Our routine and preventative services keep your pump running smoothly and prevent unexpected breakdowns.

- Repair: Swift and Efficient: Our prompt repair services ensure minimal disruption and a quick return to operation.

- Modernization: We offer modernization services to keep your pump system up-to-date with the latest technology and performance standards.

FAQs

Contact Us for Expert Solutions

Ready to optimize your industrial processes with the efficient and reliable NEMO® BF Hopper Shaped Pump with aBP-Module®? Our team of experts provide personalized advice and solutions tailored to your specific needs.

Your contacts and companies at NETZSCH

Any specific questions? Contact us for help or fill in the contact form.