19.02.2024

NETZSCH CIP Capable Sanitary Pumps for Hygienic Applications

Efficient cleaning, Reliable Product Integrity, Increased Productivity, and Sustainable cost savings: This is precisely what CIP-capable pumps from NETZSCH offer you. As a global specialist in handling complex media, NETZSCH Pumps & Systems has various hygienic/sanitary pump technologies and models in its portfolio.

We are presenting here the benefits of CIP-capable pumps that can be used in a wide range of applications in the food & beverage, cosmetic, and pharmaceutical industries.

Customised Consulting

Importance of CIP-Capable Pumps

What does CIP stand for?

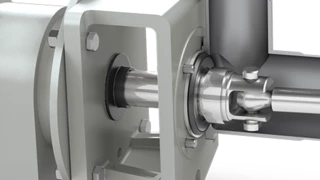

CIP means “Cleaning in Place”. It is a method of cleaning the production systems, pipelines, tanks, and other equipment, such as pumps, without dismantling them. CIP enables efficient and thorough equipment cleaning to remove impurities, residues, or bacteria. This feature benefits food, pharmaceuticals, and beverage production, where strict hygiene standards must be maintained. CIP systems are often used with special CIP-capable equipment such as pumps, valves , and piping to ensure an automated and standardized cleaning process.

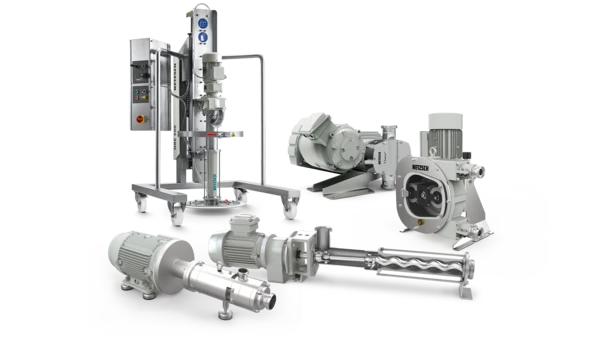

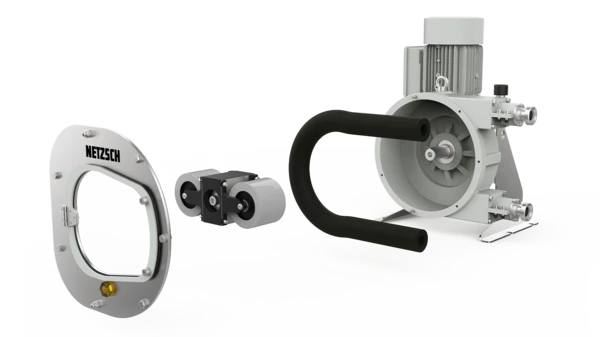

All the NETZSCH Four pump technologies, NEMO® Progressing cavity pump, TORNADO® Rotary Lobe Pump, PERIPRO® Peristaltic Hose Pump, and NOTOS® Multi Screw Pumps come with CIP Capability Versions to enhance the cleaning process and ensure to achieve desired product integrity and productivity.

Enhancing Cleaning Efficiency

NETZSCH’s Hygienic CIP-capable pumps are innovatively designed to maximize cleaning efficiency. Key benefits include:

The pumps maintain steady flow rates of cleaning solutions, ensuring thorough coverage and effective removal of residues.NETZSCH Sanitary Pumps are built to withstand high temperatures and abrasiveness, these pumps ensure that cleaning of residues from the processes is effective and sustainable. With CIP capable pump version, there is no need for manual disassembly, which significantly reduces equipment downtime and enhances productivity.

CIP Capable Pumps: Boosting Productivity Sustainably

NETZSCH CIP capable pump’s ability to automate the cleaning process and carry it out without costly downtimes optimizes the overall performance of your system. Reducing manual cleaning frees up valuable production hours, leading to increased overall productivity. Automated cleaning ensures consistent and standardized cleaning quality, which is crucial in industries with stringent quality standards like food and pharmaceuticals. Additionally, streamlining the production processes by saving both time and resources. This results in improved productivity and profitability for the plant.

Effective consumption of cleaning agents, water and energy, thanks to CIP capable pumps

By allowing precise control and automation of cleaning processes, CIP-capable pumps optimize the use of cleaning agents, water, and energy. Targeted cleaning cycles minimize the consumption of these resources without compromising cleaning effectiveness. Automating the cleaning process not only reduces water usage and waste but also improves the energy efficiency of your system. Consequently, CIP-capable pumps ensure adherence to strict hygiene standards while promoting sustainable and resource-efficient operation in production facilities.

50.000

How to reduce your costs thanks to CIP capable pumps

While the initial investment in CIP-enabled equipment might be higher, the long-term benefits are substantial. Automating the cleaning process reduces the need for manual labor, thereby lowering labor costs. Moreover, efficient cleaning without downtime boosts plant utilization and overall productivity. Precise control of cleaning cycles also minimizes the consumption of cleaning agents, water, and energy.

Additionally, these pumps help prevent cross-contamination and ensure compliance with stringent hygiene standards, all of which contribute to improved cost efficiency and a competitive edge in the market. This way, CIP-capable pumps can deliver significant savings in industrial process plants.

NETZSCH CIP-Capable Pumps

NETZSCH offers a range of CIP-capable pump technologies designed to enhance productivity and efficiency. These pumps allow effective cleaning and sterilization without the need for additional auxiliary systems or pumps.

These CIP-capable pumps ensure significant cost savings and optimized performance. Don’t miss out on the opportunity to elevate your operational efficiency.

Contact the experts at NETZSCH to find the optimal CIP-capable pump solution tailored to your specific application.