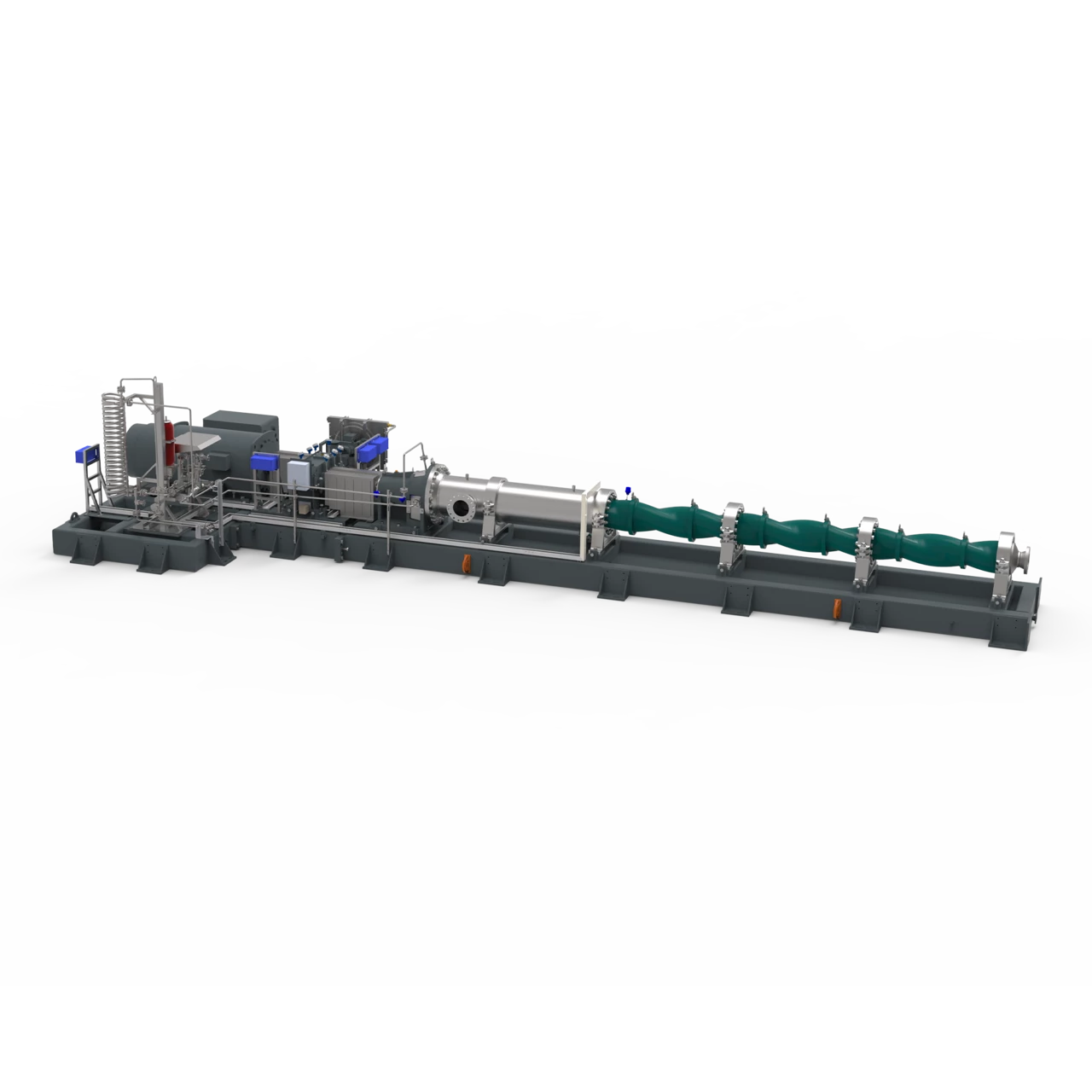

The NEMO® L.Cap® Pumps by NETZSCH is a high-performance series of progressing cavity pumps designed to handle large volumes of fluids under low and high-pressure conditions, particularly in industries such as oil and gas and mining among others. These pumps are engineered to transport complex and challenging media, including, slurries, multiphase mixtures, high-viscosity fluids, and fluids with high solid content, over long distances with minimal wear and pulsation. The L.Cap® pumps provide efficient and reliable fluid handling, reducing operational costs and maintenance requirements while ensuring stable flow in some of the most demanding industrial environments.

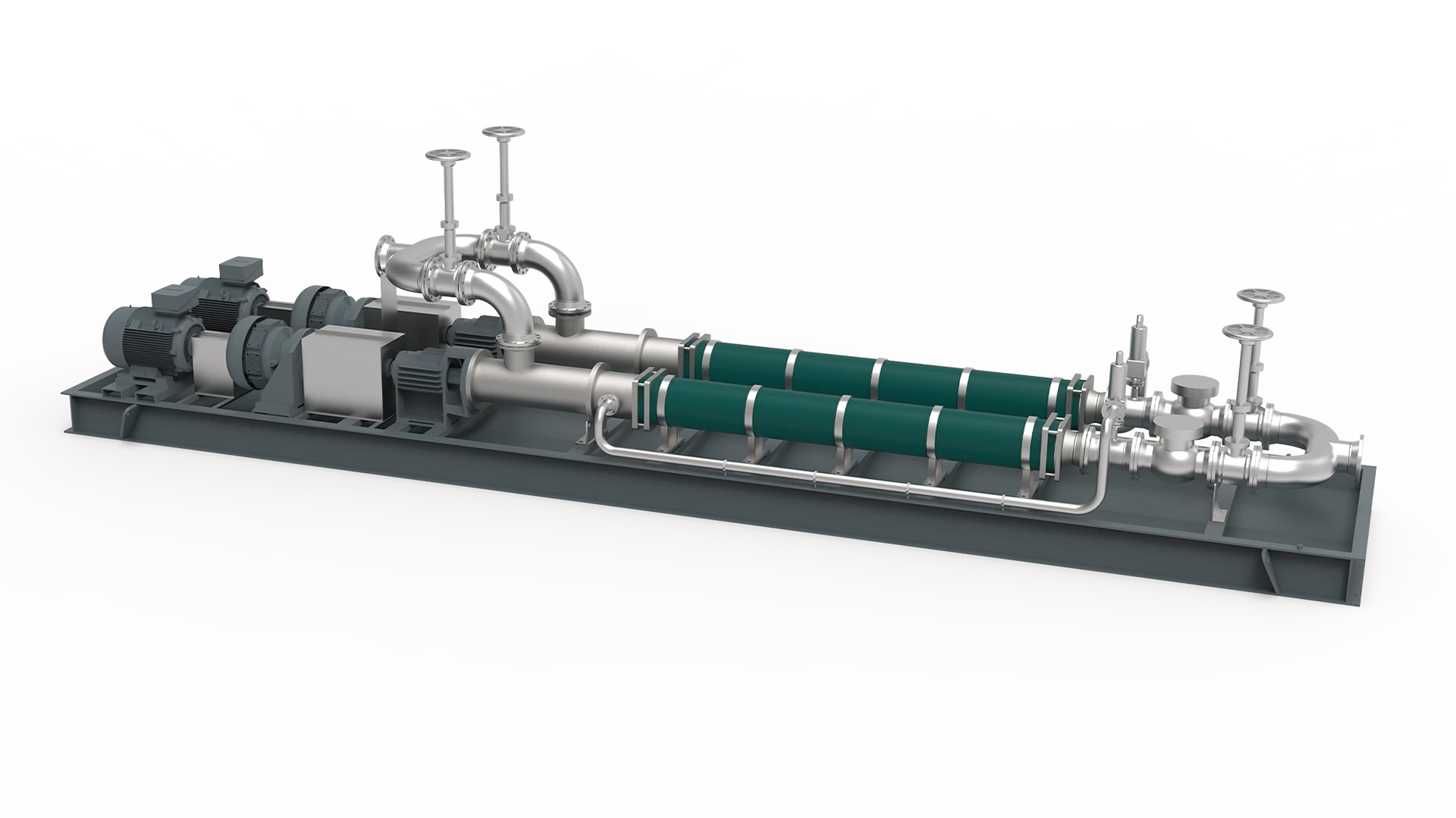

The pump’s design is versatile, offering multiple versions, single and twin designs. In the twin configuration, the suction and discharge connections are equipped with manifolds, requiring only one inlet and one outlet process connection. Both pumps typically run simultaneously, though they can operate independently during maintenance.

The vertical version is particularly effective in tank applications, with a compact and highly efficient design. The single pump design can replace multiple centrifugal or piston pumps connected in series. The L.Cap® pump is ideal for oil and water emulsions, mine dewatering, or transferring mineral slurries. Regardless of the complexity of your requirements, the NEMO® L.Cap® offers optimal technology tailored to your application and working conditions.

Individual Consulting

Advantages of NEMO® L.Cap® Progressing Cavity Pump

Highly efficient in oilfields and mining operations

No cavitation issues

Designed with low Net Positive Suction Head (NPSH) requirements, reducing the risk of cavitation and enabling more efficient operation even under low suction pressure conditions.

Long Service life

The robust construction with fewer wearing parts, reduces the frequency of maintenance and increases operational uptime.

NEMO® L.Cap® Progressing Cavity Pump Construction

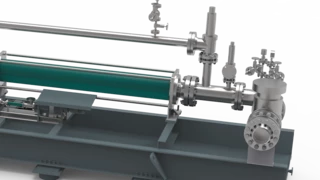

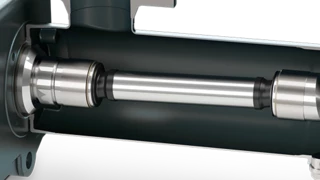

The L.Cap® pumps use the progressing cavity pump principle, where a Rotorrotor,Rotors,rotorsrotor turns inside a stator to form cavities that move the medium. This design enables the pump to handle a wide range of viscosities, solids content, and multiphase fluids. The pump components, such as the rotor and stator, are made from highly durable materials to withstand abrasive fluids and media with high solid content. The pump design also complies with API 676 standards for flow and vibration tolerances, and NACE MR-0-175, which ensure corrosion resistance and long-term durability in oil, gas, and mining applications.

The L.Cap® twin version consists of two pumps mounted in parallel on a single base plate, sharing a common suction and discharge manifold. This construction allows both pumps to operate simultaneously or individually during maintenance. In contrast, the single version is designed for moderate flow and pressure applications with a simpler configuration but similar robustness. There is also a vertical design option available, primarily for in-tank applications.

A compact and efficient pump design for tank applications. Special design considerations have been made to protect the pump from dry running, ensuring long-term durability. The pumps are mounted on a heavy-duty base plate, which allows for stable installation and ease of maintenance. This also contributes to operational safety and reliability, particularly in high-pressure environments.

The robust pump meets the highest safety standards, conforming to API 676 3rd edition and NACE MR-0-175.

Comprehensive Service and Support

At NETZSCH, our commitment to your success extends well beyond the initial purchase of your NEMO® L.Cap® Progressing Cavity Pump systems. We offer a complete range of aftermarket services to ensure your pump operates at peak efficiency and reliability throughout its lifecycle.

- Consultation: Our experts provide tailored advice to help you select the right pump configuration and optimize your processes.

- Spare Parts: We maintain a full inventory of genuine spare parts to minimize downtime and ensure optimal pump performance.

- Maintenance: Our routine and preventative services keep your pump running smoothly and prevent unexpected breakdowns.

- Repair: Swift and Efficient: Our prompt repair services ensure minimal disruption and a quick return to operation.

- Modernization: We offer modernization services to keep your pump system up-to-date with the latest technology and performance standards.

FAQs

Get in Touch for Expert Pump Advice

Discover the efficiency and reliability of our NEMO® L.Cap® Progressing Cavity Pumps. Contact our technical team today to discuss your fluid handling needs and learn how our customizable pump solutions can optimize your operations.

We offer consultation, technical support, and help in selecting the right pump for your application. Contact us now to start maximizing productivity and minimizing costs with our innovative pumping solutions.

Your contacts and companies at NETZSCH

Any specific questions? Contact us for help or fill in the contact form.