NEMO® Downhole Progressing Cavity Pumps (PCP) System by NETZSCH is designed for Oil & Gas upstream process applications, especially for pumping viscous fluids and media with high solid content. These pumps are highly efficient in various operations, which include artificial lift of heavy crude oil production to dewatering gas wells and coal seam gas extraction in Coal Bed Methane (CBM) operations. These pump systems effectively convey light to heavy crude oil with sand, water, and gas content at regulated pressure and flow rates, significantly ensuring smooth and efficient operations.

The Progressing Cavity Pump principle makes this artificial lift system ideal for heavy oil production and dewatering the CBM Wells. They offer high flexibility in managing fluid viscosity and temperature, making them suitable for wells with aggressive chemicals or extreme temperatures.

The design of NEMO® PCP Systems ensures minimal wear and tear, with fewer parts prone to wear. Several features in the pump design and expertise in the selection based on the well design clamps enhance the life cycle and reduce workovers in the installations. Additionally, the design of even-wall stators and several possible geometries in the pumping elements ensure lower operational torque and longer operational life in severe fluid conditions.

The PCP pump systems used in Artificial Lift, maintain constant pressure and flow rates while handling fluids with varying temperatures, viscosities, and solids. This design avoids emulsion effects in oil-water mixtures, simplifying surface separation. The key advantage of the PCP technology in artificial lift is its extremely high volumetric efficiency, making it efficient under challenging conditions. The volumetric efficiency of a downhole progressing cavity pump ranges between 75% and 90%, significantly higher than conventional pump systems.

PCP Pump Systems Impress with High Efficiency

In depleting oil wells, the Crude oil density comes from the wells with light oils to heavy oils with an API grade of approx 10- 31. They also come with high mixtures of sand and water, which causes variations in viscosity and abrasion on the pump system. The CBM Well operations also deal with high levels of sand cut during the dewatering operations. The NETZSCH's PCP pump systems handle these conditions effortlessly, even in low-quality oil fields.

Advantages of the Downhole PCP Pump System

Discover the unique benefits of PCP pump systems designed for optimal performance and reliability in the oil and gas upstream industry.

Viscous, Solids containing and Multi Phase liquids handling capability

High Efficiency and Energy Savings

Smooth, Pulsation-Free Flow

The design of PCPs allows for continuous, smooth flow with minimal pulsation, even when handling viscous or multiphase fluids.

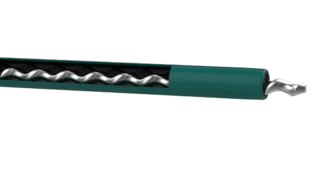

Downhole Progressing Cavity Pump System Construction

In a PCP pump system, the Rotorrotor,Rotors,rotorsrotor and stator are typically inserted at the well's lower end of the production tubing, while the rotor is connected to the surface drive unit using several sucker rods. The drive chain connected by sucker rods transmits torque from the surface drive head to the rotor. By rotating the rod string in the suction rod, with a surface drive system, the rotor turns within the stationary stator, creating the pumping action needed to deliver fluids to the surface.

The stator is an elastomer vulcanized in a tube. The elastomer stator materials are selected from a wide array of elastomer compounds. This range helps to deal with the thermal, chemical, and abrasion properties of the fluids. The medium of low to extremely high viscosity and temperatures, up to a maximum of 180 °C, can be conveyed at high volumetric efficiencies.

High sand, water or gas content are well handled by the elastomer materials of the PCP pump system. In exceptional cases, where the demands are to handle fluids at high temperatures full metal stators are also available. The portfolio also includes a large number of insertable PCP pumps. The system’s small outer diameter ensures straightforward and cost-effective installation.

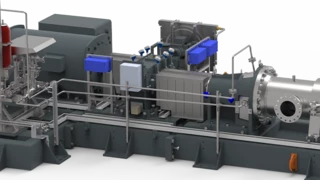

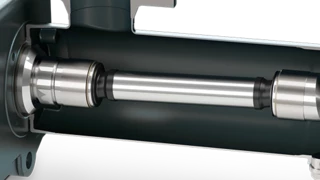

The drive head which is a surface unit to provide the torque and rotation is of a robust design and has various options in its design variants. Various sealing systems depending on the application, including mechanical seals, stuffing boxes, and lip seals are offered to prevent leaks and to protect the drive mechanism from abrasive or aggressive media. The sealing box and flange connections are exchangeable, allowing for easy maintenance.

The sucker rod is a key component in Progressing Cavity Pump (PCP) systems and surface drive mechanism systems. It serves as the connecting link between the surface drive mechanism (such as a pump jack or drive head) and the downhole pump, transferring the rotational or reciprocating motion needed to pump fluids to the surface. A torque anchor is provided to prevent the pump from rotating within the tubing. This prevents the tubing from unscrewing and ensures that the energy generated by the motor is efficiently transferred to the rotor, maximizing fluid production.

Comprehensive Service and Support

At NETZSCH, our commitment to your success extends well beyond the initial purchase of your NEMO® Downhole Progressing Cavity Pump systems. We offer a complete range of aftermarket services to ensure your pump operates at peak efficiency and reliability throughout its lifecycle.

- Consultation: Our experts provide tailored advice to help you select the right pump configuration and optimize your processes.

- Spare Parts: We maintain a full inventory of genuine spare parts to minimize downtime and ensure optimal pump performance.

- Maintenance: Our routine and preventative services keep your pump running smoothly and prevent unexpected breakdowns.

- Repair: Swift and Efficient: Our prompt repair services ensure minimal disruption and a quick return to operation.

- Modernization: We offer modernization services to keep your pump system up-to-date with the latest technology and performance standards.

FAQs

Get in Touch for Expert Pump Advice

Discover the efficiency and reliability of our PCP Pump Systems. Contact our technical team to discuss your fluid handling needs and learn how our customizable pump solutions can optimize your operations. We offer consultation, technical support, and help in selecting the right pump for your application.

Your contacts and companies at NETZSCH

Any specific questions? Contact us for help or fill in the contact form.