27.03.2024

What You Need to Know About Progressing Cavity Pumps in Malaysia

This article explores progressing cavity pumps, known in Malaysia as Moineau pumps, Mohno pumps, Moyno pumps, or mono pumps. We'll delve into their construction, function, advantages, disadvantages, and suitable applications, drawing on the expertise of NETZSCH Pumps & Systems, a global leader in this technology.

With over 70 years of experience, NETZSCH provides comprehensive knowledge on progressing cavity pumps, ensuring you have everything you need to understand this proven technology.

Customised Consulting

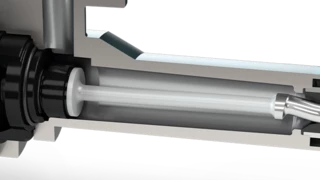

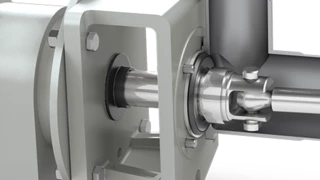

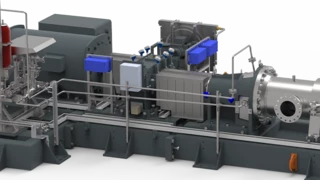

Construction of Progressing Cavity Pumps

Progressing cavity pumps are highly suitable for efficiently pumping various media in Malaysia. They consist of several key components:

- Rotorrotor,Rotors,rotorsRotor: The central moving part, positioned eccentrically within the pump housing.

- Stator:The stationary, elastic housing encasing the Rotorrotor,Rotors,rotorsrotor, with a unique internal geometry that matches the rotor's external form. It is often made of rubber-like materials for a tight seal.

- Pump housing:The outer metal frame enclosing the stator and containing the pumped liquid.

- Inlet and outlet openings: Where the fluid enters and exits the pump.

- Drive unit: Electric motor, hydraulic motor, or other rotor mechanisms.

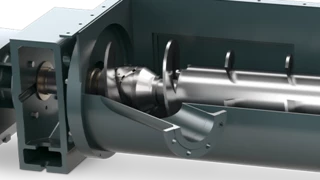

Function of Progressing Cavity Pumps

These pumps utilize the positive displacement principle, where an eccentrically rotating rotor forms progressively increasing cavities within the elastic stator. During the inlet phase, the pumped medium is drawn into this cavity. As the rotor spins, it continuously pushes the medium in front of it, transporting it from the inlet to the outlet precisely. The tight fit between the rotor and stator ensures efficient sealing, enabling the handling of viscous, abrasive media with minimal pulsation and pump damage.

Advantages of Progressing Cavity Pumps in Malaysia

Several advantages make progressing cavity pumps attractive for various industrial applications in Malaysia:

- Gentle and Precise Handling: The positive displacement principle makes it ideal for pumping various viscous media, slurries, and suspensions.

- Low Pulsation: Minimizes wear on pump components and ensures consistent pumping.

- Efficient Sealing: Tight fit between rotor and stator minimizes pressure loss.

- Damage-Free Handling: Can handle sensitive media without harm.

- Versatility, High Efficiency, and Easy Maintenance Make them popular in various industries.

Heating

Versatility

Disadvantages of Progressing Cavity Pumps

Despite their advantages, progressing cavity pumps also have some potential drawbacks:

- Sensitivity to Dry Running: This can increase wear if improperly lubricated.

- Limited Pumping Speed: Compared to other pump types, their speed might not be suitable for high flow rate applications.

- Material Requirements: Certain media might necessitate specific rotor and stator materials to minimize corrosion and abrasion.

- Cleaning and Maintenance Challenges: The complex pump geometry can make cleaning and maintenance more difficult.

It's important to remember that the extent to which these drawbacks manifest depends heavily on the specific context. Careful selection, installation, and maintenance can significantly minimize the impact of many of these limitations. NETZSCH's experts are readily available to advise and assist you in choosing the right technology for your needs in Malaysia. Their comprehensive support extends beyond purchase, encompassing advice, maintenance, spare parts, repairs, and pump modernization. Their global service network ensures they are prepared to assist you around the clock in emergencies.

Due to its optimal process characteristics, the NEMO® BH hygienic pump exemplifies the use of progressing cavity pumps in Malaysia's sanitary applications.

Areas of Application for Progressing Cavity Pumps in Malaysia

The versatile properties of progressing cavity pumps make them suitable for various industries in Malaysia:

- Food Processing: Gentle transfer of viscous substances like sauces, doughs, or creams.

- Chemical Industry: Handling abrasive and aggressive media, reducing long-term maintenance and repair costs.

- Wastewater Treatment: Pumping sludge and sewage sludge, even with solid components.

- Oil and Gas Industry: Sustainable solutions for transferring drilling mud.

- Pharmaceutical Industry, Paper Production, and Mining: Efficient pumping of diverse media with varying consistencies.

Therefore, progressing cavity pumps are used in various Malaysian industries that require precise, gentle, and reliable pumping of different media.

Progressing Cavity Pumps from NETZSCH in Malaysia

As a global leader in conveying complex media, NETZSCH offers a comprehensive portfolio includes rotary lobe pumps, multi screw pumps, peristaltic pumps, grinding systems and barrel emptying systems as well as progressing cavity pumps.

The diverse range of NETZSCH offerings allows them to address the unique needs of numerous industries within Malaysia:

- Environment & Energy

- Chemical Pulp & Paper

- Food & Pharmaceuticals

- Mining

- Oil & Gas Upstream

- Oil Gas Mid- / Downstream

- Batteries

NETZSCH's global reach ensures they can develop customized and sophisticated pump solutions tailored to your specific requirements in Malaysia.