APPLICATIONS & SOLUTIONS

NETZSCH Pump Solutions for the Food & Pharmaceutical Sectors

เราคิดค้น และพัฒนา positive displacement pump ที่สมบูรณ์แบบสำหรับการใช้งานทุกรูปแบบ

ในฐานะผู้ผลิต และจำหน่ายชั้นนำของโลกด้าน positive displacement pumps บริษัท NETZSCH ขอนำเสนอวิธีการ และนวัตกรรมที่เหมาะสม ในการใช้งานด้านอาหาร และยา ด้วยผลิตภัณฑ์ระบบปั๊ม ของเรา โดยลูกค้าสามารถลำเลียงผลิตภัณฑ์ได้อย่างเหมาะสม และสะอาดตามหลักเกณฑ์สุขอนามัย

เนื่องจากมีการใช้งานที่หลากหลายของกลุ่มอาหารและยา พวกเราจึงทำการพัฒนาปรับแต่ง อย่างพิถีพิถันในแก้ปัญหาของปั๊มเพื่อตอบโจทย์ความต้องการทั่วโลก เราจึงขอสัญญาว่า Proven Excellence จะให้ความมั่นคงด้านประสิทธิภาพการทำงานในทุกด้าน

ไม่ว่าจะเป็น อุตสาหกรรมเครื่องดื่ม, การผลิตอาหาร, เครื่องสำอาง หรือยา, กลุ่มผลิตภัณฑ์ที่ทำจากนม หรือการลำเลียงน้ำมันและไขมัน ตามความต้องการของลูกค้า เพราะความพึงพอใจของลูกค้าเป็นสิ่งสำคัญที่สุดของเราเสมอ

Individual Consulting

Special challenge: High hygienic standards

“In food processing, the production of cosmetics and the pharmaceutical industry in particular, we have to take special care with regard to the consumer. This of course means that all NEMO® and TORNADO® pumps are made according to the nationally and internationally relevant manufacturing and hygiene standards and guidelines.”

To be approved for use in the food and pharmaceutical industries, pumps from NETZSCH are subject to a whole range of hygienic guidelines, from the EHEDG to the 3-A Sanitary Standard to specifications from the US Food and Drug Administration (FDA). Our pumps and systems open up new possibilities for you and your manufacturing processes.

Practical experience from food and pharmaceuticals

Discover first-hand advantages of our solutions in action and the crucial role our service plays in ensuring smooth operation. Customers from the food and pharmaceutical sectors report on their experiences with NETZSCH.

Hygienic pumping of liquids and emptying of barrels

ในอุตสาหกรรมอาหารและเครื่องดื่ม การส่งผลิตภัณฑ์อย่างนุ่มนวลตามมาตรฐานด้านสุขอนามัยที่เป็นสิ่งสำคัญ ด้วย oil-free TORNADO® T.Sano® rotary lobe pump ผู้ใช้งานสามารถส่ง sparkling และ semi-sparkling wines ได้อย่างแม่นยำและคงที่ในเวลาเดียวกัน ด้วยพื้นฐานของการสูบ ตามหลักการ positive displacement pump จึงไม่มีความผันผวนของแรงดันหรือแรงกระทำกับของเหลว (shear force) จึงสามารถป้องกันการเกิดฟองที่ไม่ต้องการ ด้วยระบบพิเศษในการสูบของเหลวออกจากถัง barrel (barrel emptying system) ของเรา สามารถลำเลียงของเหลวออกจาก barrel ได้โดยไม่มีสารตกค้างตามมาตรฐาน hygienic ในหน้างานที่พื้นที่จำกัด TORNADO® T.Sano® rotary lobe pump ก็เหมาะสำหรับการลำเลียงของเหลวออกจาก barrel เช่นกัน จากการออกแบบนวัตกรรมทำให้สามารถลำเลียงผลิตภัณฑ์ได้หลากหลายภายใต้มาตรฐานสูงสุดด้านสุขอนามัย

Efficient and temperature-controlled conveying of critical media

Hygienic, flexible and gentle transport of edible oils and fats

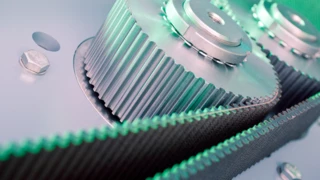

การสูบน้ำมันบริโภค และส่วนประกอบของไขมันจะมีความต้องการที่หลากหลาย นอกจากเงื่อนไขด้านสุขอนามัย ด้วย TORNADO® T.Sano® rotary lobe pump ที่มีต้นทุนในการบำรุงรักษาที่ต่ำ อีกทั้ง rotary lobe pump ยังให้การสูบที่นุ่มนวล และมีประสิทธิภาพ จึงทำให้เหมาะสำหรับการผลิตผลิตภัณฑ์ เช่น มายองเนส ด้วยการออกแบบนวัตกรรมระบบขับเคลื่อนด้วยสายพานที่เป็นลักษณะเฉพาะ ทำให้มีความยืดหยุ่นสูงในทุกการใช้งาน อีกทั้งยังสามารถติดตั้ง T.Sano® ลงบนแท่นแบบเคลื่อนที่ได้อีกด้วย

Hygienic and reliable conveying in dairies

ผลิตภัณฑ์ที่ต้องการความพิถีพิถันอย่างมากในการสูบ เช่น โยเกิร์ต, นม, นมข้นหวาน หรือผลิตภัณฑ์ที่ทำมาจากนม จำเป็นที่จะต้องมีการลำเลียงแบบนุ่มนวลเป็นพิเศษโดยเป็นไปตามมาตรฐานสุขอนามัยอย่างเข้มงวด ด้วย NEMO® progressing cavity pump สามารถส่งผลิตภัณฑ์ได้ตามความต้องการโดยไม่เกิดการสึกหรอ และไม่มีการใช้น้ำมันหล่อลื่น เพื่อการส่งผลิตภัณฑ์โดยปราศจากเชื้อ และช่วยป้องกันการปนเปื้อน ด้วยการออกแบบไม่ให้มีพื้นที่สำหรับการหมักหมม อีกทั้ง progressing cavity pump สามารถทำความสะอาดได้โดยปราศจากสารตกค้าง ประหยัดเวลา ค่าใช้จ่ายในการซ่อมบำรุง และเพิ่มประสิทธิภาพในการผลิต