APPLICATIONS & SOLUTIONS

NETZSCH Pump Solutions in the Mining Sector

We find and develop the perfect positive displacement pump for your individual application

As the world's leading supplier of positive displacement pumps, NETZSCH offers you customised pump solutions in the field of mining. Our pumps and systems guarantee the pumping of explosive media in compliance with the highest safety standards.

On a global basis, we work together with you to develop pump solutions in the mining sector that are optimised for you and your application. Whether wastewater, mineral slurries, thickened slurries, kaolin suspensions, filtrates, tailings or explosives, NETZSCH always guarantees you the right solution for your process. We promise you Proven Excellence – outstanding performance in all areas.

Whether wastewater, mineral slurries, thickened slurries, kaolin suspensions, filtrates, tailings or explosives, NETZSCH always guarantees you the right solution for your process. We promise you Proven Excellence - outstanding performance in all areas.

Individual Consulting

The right pump for your mining application

“Our innovative pumping solutions for the mining and explosives market focus on customer needs. Thanks to the diversity of positive displacement pumps in our portfolio, we can handle even the most complex fluids safely, bringing a reliable solution that will secure and maintain production with long-term cost efficiency. We provide you with a global network to meet your demands in mining applications.”

We make no compromises when it comes to the safety of our customers. For our NEMO® progressing cavity pumps, PERIPRO peristaltic pumps, TORNADO® rotary lobe pumps, NOTOS® multi screw pumps and grinders, even partially demanding media in mining do not cause any problems. Together with you, we will find or develop an optimally adapted product for you and your requirements. Your satisfaction is always our top priority.

Practical experiences from the mining sector

Discover first-hand advantages of our solutions in action and the crucial role our service plays in ensuring smooth operation. Customers from the mining sector report on their experiences with NETZSCH.

“In terms of value, NETZSCH products are durable and reliable, offering long-term cost savings. The pumps, like the NEMO® progressing cavity pump, deliver great all-round performance under varying conditions, essential for our operations. Overall, NETZSCH’s combination of superior customer service, expert knowledge, and high-performing products makes them a trusted partner for our business. Operating in the harshness of the mining industry these pumps continue to impress.”

We make no compromises when it comes to the safety of our customers. For our NEMO® progressing cavity pumps, PERIPRO peristaltic pumps, TORNADO® rotary lobe pumps, NOTOS® multi screw pumps and grinders, even partially demanding media in mining do not cause any problems. Together with you, we will find or develop an optimally adapted product for you and your requirements. Your satisfaction is always our top priority.

Long service life when pumping aggressive sludge

Pumps and systems are exposed to particularly high loads when pumping sludge in mining. NEMO® progressing cavity pumps offer you a particularly long service life, for example, when pumping aggressive gold slurry, even without adding water. In addition, our progressing cavity pumps are easy to clean and maintain. As a result, you can significantly reduce your operating and maintenance costs. This simplifies your process and increases the service life at the same time.

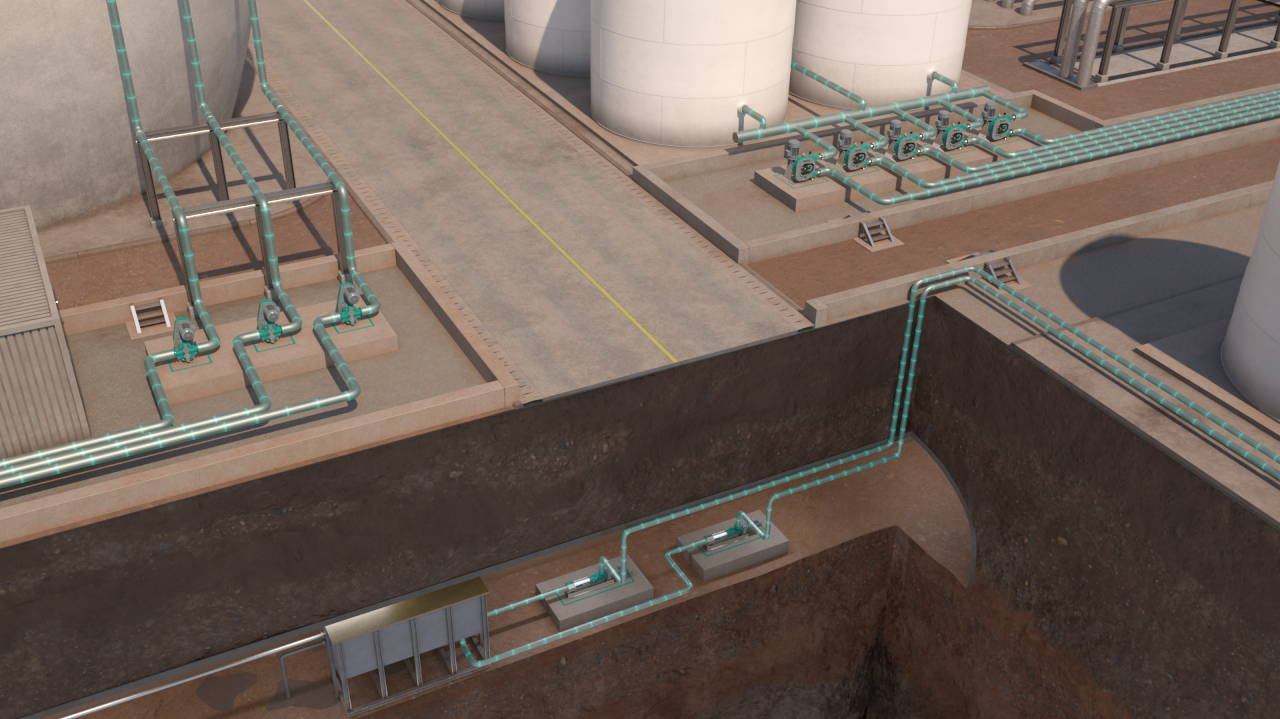

Copper preparation with highest precision and reliability

Special applications require unique solutions: Precision and reliability play a decisive role in copper processing. Thanks to our broad product portfolio and the systems individually adapted to you, you can significantly reduce your maintenance effort. A customised plug-and-play system with pre-assembled pumps, for example, enables you to make various adaptations for the most diverse challenges. This means you always remain flexible.

Mobile and ATEX-compliant conveying of emulsified explosives

Safety plays a central role when conveying emulsified explosives. NEMO® progressing cavity pumps guarantee you transport in compliance with the highest safety precautions and are ATEX-compliant. Moreover, by mounting them on mobile mixer-loading vehicles, you are not tied to a specific location. In addition, the progressing cavity pump offers you two inspection openings, which are mounted above the joints of the coupling rod. During operation, this allows you to check whether the joints are still sufficiently lubricated and the seals are still intact. Thus, nothing stops a safe promotion.

Safe conveying of emulsions in mining operations

NEMO® progressing cavity pumps offer you maximum safety and long service life at the same time. When transporting sharp explosives such as ammonium nitrate emulsion in mining operations, safety is the top priority. This is guaranteed by a double-acting mechanical seal and additional control mechanisms. Thanks to the innovative concept, you can further optimise your process. The NEMO® joint also gives you a long service life with maximum throughput at the same time.