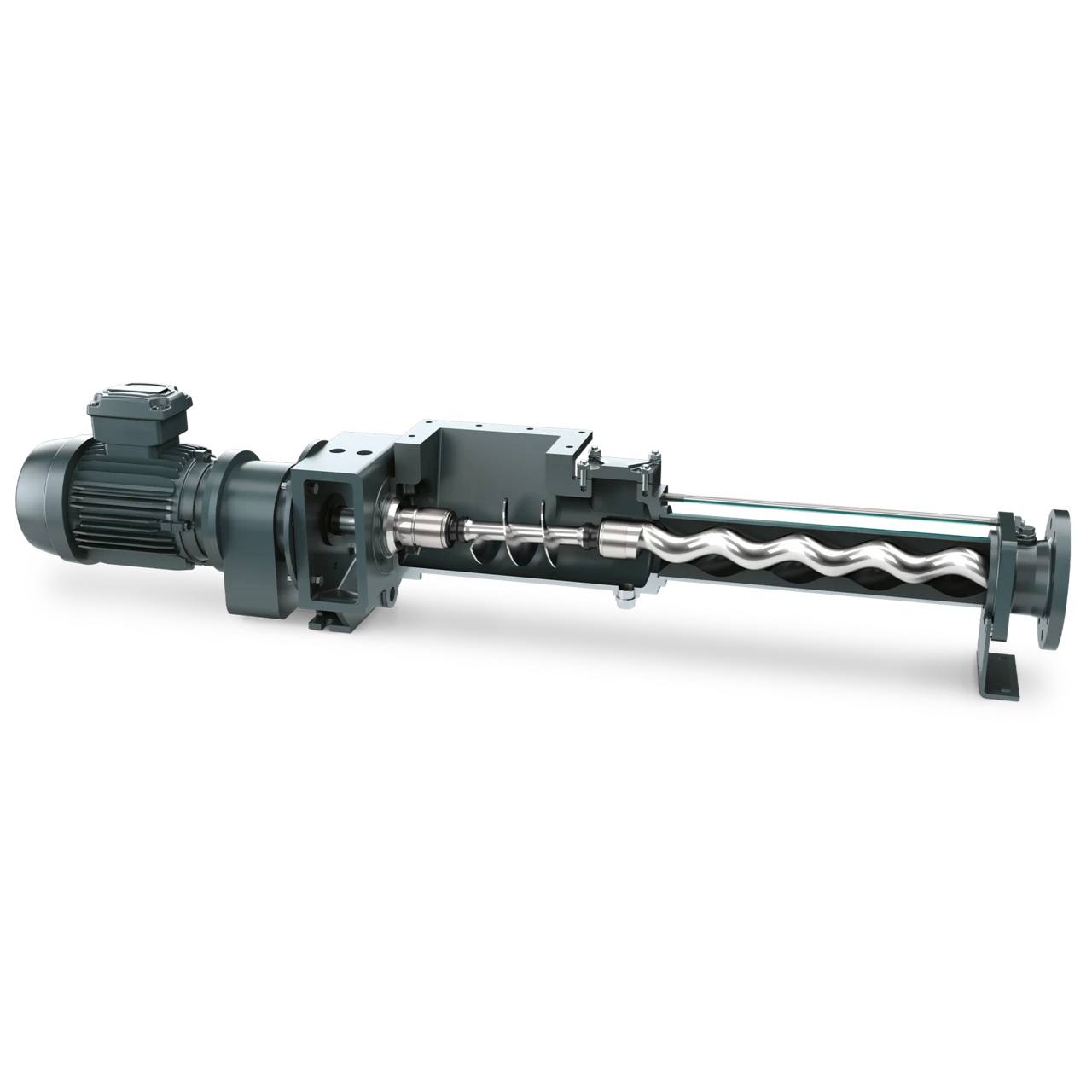

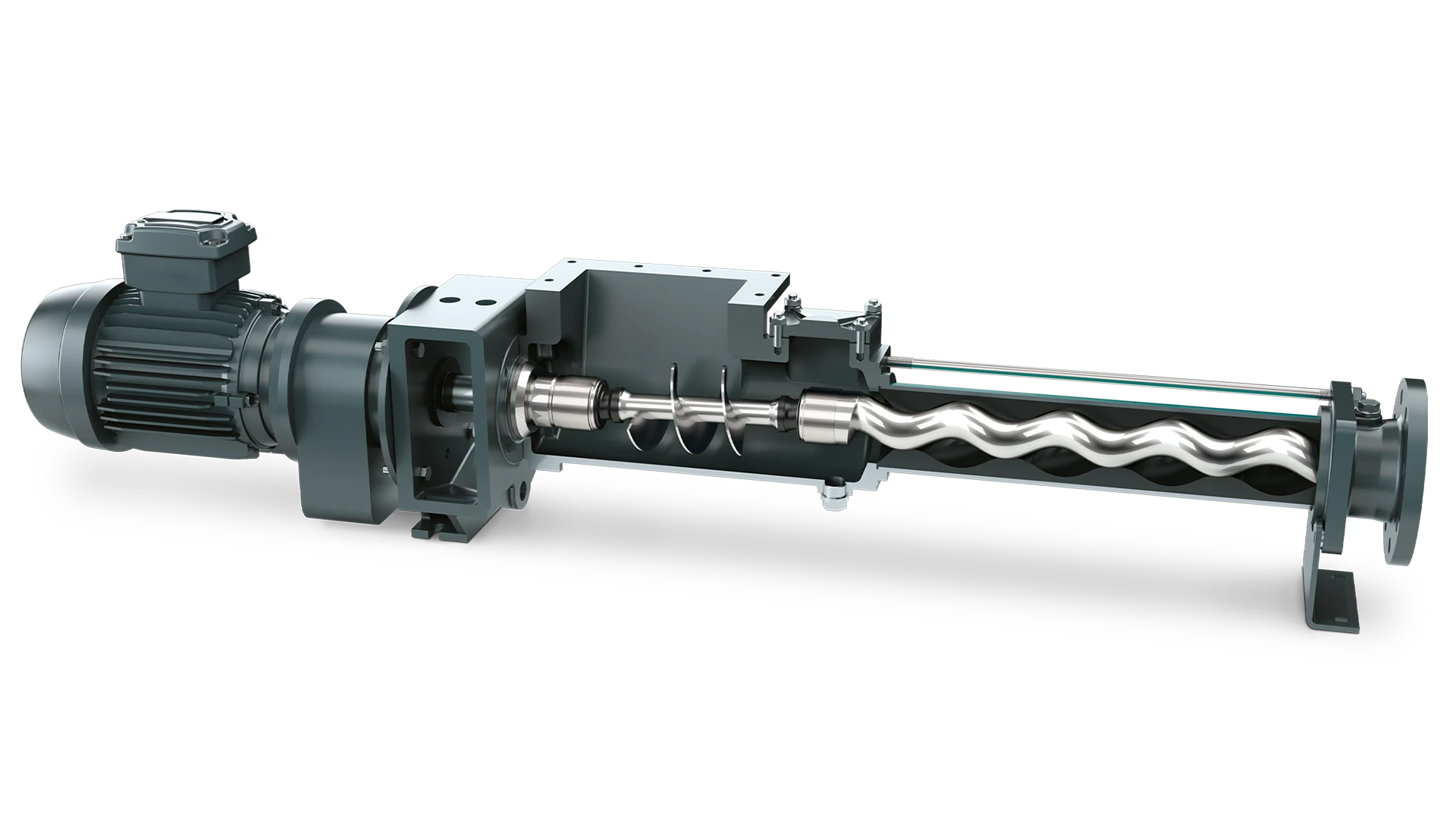

The NEMO® BO/BS hopper design progressing cavity pump in block construction is the ideal solution for handling highly viscous and fibrous media that doesn’t flow freely. This pump is also ideal for liquids with solid content, shear-sensitive, non-lubricating, thixotropic, and dilatant media across diverse industries.

The pump is designed for efficiency, reliability, and continuous operation. This progressing cavity pump features a hopper and coupling rod with a feeding screw, along with a force-feed chamber, to enhance smooth and continuous product feed into the conveying elements.

This pump design is ideal and best suited for applications within wastewater treatment, food processing, chemicals, paper, and various other process industries, providing a compact and reliable solution that ensures continuous, gentle, and low-pulsation conveying of various challenging media.

Individual Consulting

Advantages of NEMO® BO/BS Progressing Cavity Pump

Viscous Media Handling

Wide Flow and Pressure Range

Engineered Designs

NEMO® BO/BS Progressing Cavity Pump Construction

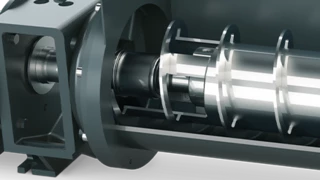

The NEMO® BO/BS Progressing Cavity Pump is constructed with a suction housing that is either a rectangular or quadratic feed hopper. It has a coupling rod with a gentle conveying screw and a compression chamber for improved product feeding into the pumping elements.

The BO Series features a rectangular inlet hopper for smoother flow for non-flowing liquids and BS Series features a square inlet hopper which has a more compact footprint for specific installations that need space saving designs.

The hopper dimensions can be adapted to the individual application based on the feeding or upstream equipment. The pump housing can be designed with materials in steel, chrome-nickel-steel or stainless steel and also with special materials upon request. The stator is vulcanized into the housing with sealing on both sides in a variety of elastomers. Stator inlet is designed with hopper-shaped opening for improved feed of the product into the conveying chamber.

Shaft seals are standard seals with single-acting, bi-directional, and wear-resistant. Upon request, with single- or double-acting mechanical seals of varied designs and from various manufacturers, cartridge and special seals as well as packed glands are available based on the complexity of the application.

The NEMO® BO/BS in block design with directly flanged drive and the other model NEMO® SO/SS with bearing housing and drive shaft are ideal for handling higher axial loads and pressures when handling highly viscous, crumbly, and solids-containing media in diverse process industries.

Comprehensive Service and Support

At NETZSCH, our commitment to your success extends well beyond the initial purchase of your NEMO® BO/BS Progressing Cavity Pump. We offer a complete range of aftermarket services to ensure your pump operates at peak efficiency and reliability throughout its lifecycle.

- Consultation: Our experts provide tailored advice to help you select the right pump configuration and optimize your processes.

- Spare Parts: We maintain a full inventory of genuine spare parts to minimize downtime and ensure optimal pump performance.

- Maintenance: Our routine and preventative services keep your pump running smoothly and prevent unexpected breakdowns.

- Repair: Swift and Efficient: Our prompt repair services ensure minimal disruption and a quick return to operation.

- Modernization: We offer modernization services to keep your pump system up-to-date with the latest technology and performance standards.

FAQs

Contact Us for Expert Solutions

Ready to optimize your industrial processes with the efficient and reliable NEMO® BO/BS Pump with Hopper in Block Construction? Our team of experts provide personalized advice and solutions tailored to your specific needs.

Your contacts and companies at NETZSCH

Any specific questions? Contact us for help or fill in the contact form.