The NEMO® BO/SO hopper pump with integrated cutting device seamlessly combines the cutting and conveying of large particles. Designed to streamline processes and eliminate the need for costly additional equipment, this innovative pump offers efficient cutting and conveying in a single process step and can be an ideal pump solution for the food industry.

With its integrated cutting device, the NEMO® BO/SO pump can handle a wide range of applications across various sectors for liquids with a viscosity of about 5000 cP. In food processing, the pump excels at chopping and pumping large solids in applications like conveying watery vegetables and prepares them for further processing with ease and speed.

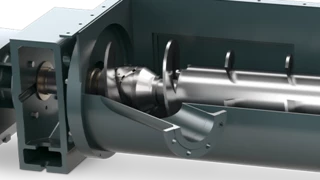

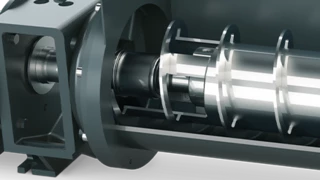

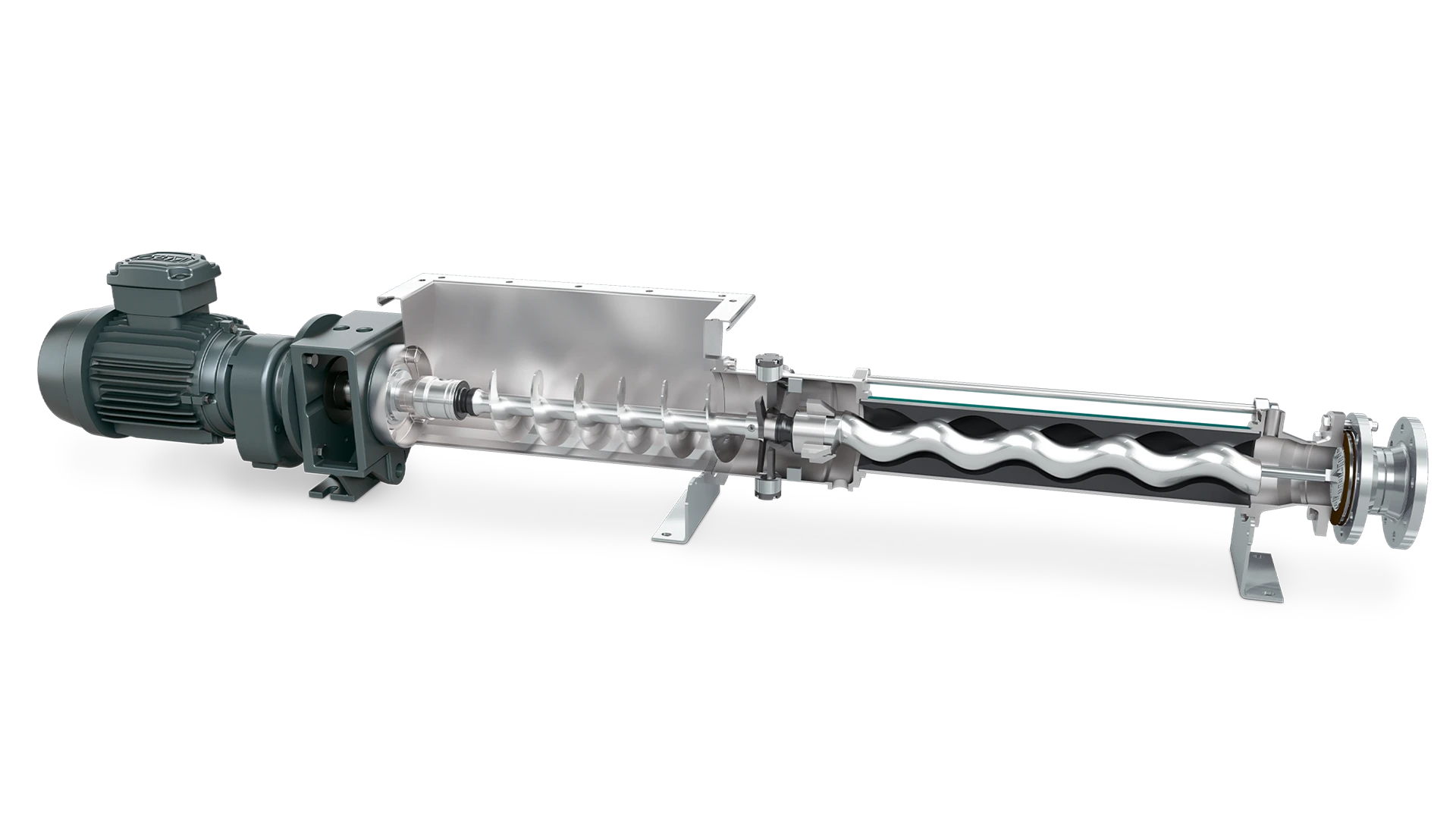

At the heart of the NEMO® BO/SO progressing cavity pump is its progressing cavity technology, which ensures continuous, pressure-stable, gentle, and low-pulsation conveyance.

The NEMO® BO/SO Hopper Pump with cutting device efficiently manages viscous to non-free-flowing media, whether containing solids or not, making it a reliable pump solution in a wide range of industrial processes.

NEMO® BO/SO: Two process steps with only one pump

Optionally the pump can be equipped with an additional cutting unit at the discharge flange of the pump. With its perforated disc and rotating knife, it allows for further fine definition of the particle size.

As with any other NEMO®progressing cavity pump also the BO/SO pump has the ability to dose the conveyed media in proportion to rotation speed. In block construction with a flanged drive, this pump is particularly compact and economical in addition, the NEMO® is characterized by low investment, operating, and maintenance costs.

However, it is also available in bearing block design with a free shaft end. This means that the pump can be operated with different types of drive, such as servo motors, diesel engines, or hydraulic drives.

Individual Consulting

Advantages of NEMO® BO/SO Hopper Pump With Cutting Device

Continuous Low-Pulsation Conveyance

Ease of Service

Replacing Additional Machinery

NEMO® BO/SO Hopper Pump With Cutting Device Construction

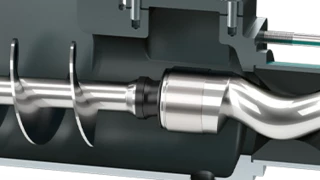

The NEMO® BO/SO progressing cavity pump is designed with a hopper to enable ease of production flow in the suction, the coupling rod with a feeding screw, and a set of cutters in force-feed chamber to provide continuous, pressure-stable, gentle, and low-pulsation cutting and conveyance.

The hopper housing with a cutting unit guarantees an optimum size reduction of chunky solids into the pump conveying elements. The larger fruits and vegetables are cut immediately once the medium passes the force-feed/compression chamber with the cutting device.

This unit consists of a rotating knife with three blades and a variable number of stationary knives adjustable to the size and consistency of the particles. Optionally the pump can be equipped with an additional cutting unit at the discharge flange of the pump. With its perforated disc and rotating knife, it allows for further fine definition of the particle size.

This special version of a NEMO® BO/SO hopper pump with cutting device has been designed for applications in the food industry.

Comprehensive Service and Support

At NETZSCH, our commitment to your success extends well beyond the initial purchase of your NEMO® BO/SO Progressing Cavity Pump. We offer a complete range of aftermarket services to ensure your pump operates at peak efficiency and reliability throughout its lifecycle.

- Consultation: Our experts provide tailored advice to help you select the right pump configuration and optimize your processes.

- Spare Parts: We maintain a full inventory of genuine spare parts to minimize downtime and ensure optimal pump performance.

- Maintenance: Our routine and preventative services keep your pump running smoothly and prevent unexpected breakdowns.

- Repair: Swift and Efficient: Our prompt repair services ensure minimal disruption and a quick return to operation.

- Modernization: We offer modernization services to keep your pump system up-to-date with the latest technology and performance standards.

FAQs

Contact Us for Expert Solutions

Ready to enhance your food processing applications with the NEMO® BO/SO Hopper Pump with a cutting device? Our team of technical experts provide personalized advice and solutions tailored to your specific needs.

Your contacts and companies at NETZSCH

Any specific questions? Contact us for help or fill in the contact form.