28.10.2024

Maximize Biogas Yield with NETZSCH Pumps: Reliable and efficient solutions for Biogas Industry

The biogas industry in India is booming in the country's renewable energy landscape, addressing both energy needs and waste management challenges. With large agricultural lands and significant quantities of organic waste, India has vast potential for biogas production.

India aims to significantly scale up its biogas production capacity, particularly through large-scale commercial plants and the promotion of CBG as a sustainable fuel for transportation, aligning with the commitment to reducing carbon emissions.

However, to fully realize biogas's potential, the production process's efficiency and reliability are paramount. This is where NETZSCH Pumps & Systems India, the global specialist in complex fluid management, offers optimal pump solutions designed specifically to enhance the efficiency and reliability of biogas production processes and ensure consistent, long-term performance.

Customised Consulting

Biogas Production and the Importance of Pumps & Systems

Biogas production is a complex process that involves the anaerobic digestion of organic materials, such as agricultural waste, manure, and food waste. This process requires the movement and management of various substrates and byproducts throughout different stages, including feeding the digester, fermenter, recirculating digestate, and handling the output. The efficiency and reliability of these operations are heavily dependent on the quality of the pumping systems used.

Why NETZSCH Pumps & Systems for Biogas Production?

- High Yield: Optimized efficiency with homogenized mixing and conveying of substrates, maximizing biogas yield.

- Robust pump design: Built to withstand abrasive and solids consistency, ensuring long-term reliability.

- Precise Flow: Consistent Flow, though with high viscous & large solids size.

- Versatile Solutions: Offers a range of pumps and grinding systems customized to various processes of biogas production.

- Low life cycle costs: Reduces operational costs with reliable performance and minimal and easy maintenance.

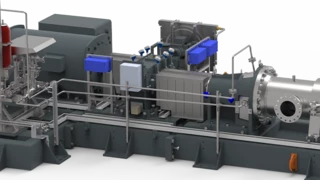

NETZSCH Pumps & Grinding Systems

NETZSCH offers a wide range of products designed to meet the needs of biogas production process, the NEMO® progressing cavity pumps, TORNADO® rotary lobe pumps, and M-Ovas®, N.Mac® grinding systems are known for their high quality, durability, and efficiency, making them ideal for biogas production.

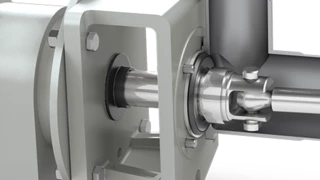

NEMO® Progressing Cavity Pumps

The NEMO® B.Max® mixing and conveying pump ensures homogenous mixing and conveying of substrates with high dissolved solid contents up to 15 %. The pump is designed to a proper mixing efficiency to ensure highest level of efficacy of solids to provide maximum yield in the biogas production.

Application: Ideal for handling viscous, abrasive, and solid-laden substrates from various sources of feedstock such as animal litter, press mud, Napier grass, and paddy straw.

Features: Provides Consistent mixing and flow, with excellent endurance during operations.

Benefits: High efficiency, low pulsation, and the ability to handle a wide range of viscosities.

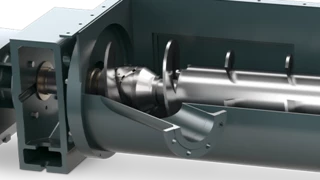

TORNADO® Rotary Lobe Pumps

The Robust & compact TORNADO® Rotary Lobe Pump can fit in small space areas and convey high flows reliably up to 1000m3/hr and pressures up to 10 Bar.

Application: Suitable for pumping high-viscosity liquids, as well as abrasive media for transfer and effective re-circulation.

Features: Compact design with high flow rates and the ability to operate at variable speeds. The pump is self priming and excellent for negative lift conditions.

Benefits: Robust, Easy to maintain, versatile installation, and capable of handling large solids without clogging.

M-Ovas® Grinding System & Macerator Pumps

The Grinders shred/crush the large solids in the substrates, protect the pumps and downstream units from blockages, and ensure smooth operation.

Application: Used for grinding and reducing the particle size of solid materials in wastewater treatment, food processing, and biogas production.

Features: Integrated cutting mechanism for efficient grinding of course materials, preventing clogging and ensuring smooth operation.

Benefits: Protects downstream equipment from blockages, reduces maintenance costs, improves the efficiency of downstream processes, and handles large solids with ease.

Applications in Biogas Production

Pre-Treatment Process

- Feedstock Handling and Preparation: In biogas plants, organic waste materials such as agricultural residues, food waste, and manure need to be homogeneously mixed and prepared for digestion. NETZSCH N.Mac or M-Ovas Grinding Systems are used to shred the fibrous matter or solids in the raw feed and feeds to NEMO® progressing cavity pumps for consistent and reliable feed into the digester, preventing blockages and maintaining a steady flow process.

Gas Production Process

- Feeding the Digester: The pre-treated substrate is fed into the anaerobic digester where microbial activity breaks it down to produce biogas. The NEMO Progressing cavity pumps or TORNADO Rotary Lobe Pumps based on the space availability, can be used to feed the substrate into the digester at controlled rates, ensuring optimal loading and avoiding overloading flow.

- Recirculation: Within the digester, maintaining proper mixing and preventing sedimentation is essential for efficient biogas production. NEMO Progressing Cavity pumps facilitate the recirculation of the substrate, enhancing contact between the microorganisms and the organic material, thus improving biogas yield.

- Slurry Transfer: As the digestion process continues, the digested slurry needs to be periodically removed and transferred to storage or further treatment. Again, NEMO Progressing cavity pumps or TORNADO Rotary Lobe Pumps are employed for the efficient transfer of this sludge, handling its high viscosity and solids content effectively.

Gas Purification Process

- Condensate Removal: Biogas produced in the digester contains moisture that needs to be removed to prevent damage to downstream equipment. The NEMO Progressing Cavity pumps convey chilled water and assist the process in the removal of condensate from the biogas, ensuring it is dry before further purification steps.

- CBG to CNG Upgrading: CNG production focuses on increasing methane content and eliminating impurities from Compressed Biogas (CBG). Impurities such as H2S, CO2, and N2 are removed to achieve 96% methane purity. During this process, biogas is compressed to a pressure of 9-12 bar and fed into the desorption column. Chilled water is continuously introduced at a constant volume and pressure to separate the H2S, CO2, and N2 gases. The NEMO Progressing Cavity Pump is employed to reliably deliver the water at a consistent volume and pressure, facilitating the removal of these impurities.

NETZSCH Pumps for Biogas Industry

The efficiency and reliability of the Pumps in the biogas production process can significantly impact the overall gas yield and profitability. NETZSCH pumps & systems, with their robust and advanced pump solutions, offers the ideal solution for maximizing biogas yield while minimizing operational costs and downtime. By integrating NETZSCH pumps into your biogas facility, you can ensure a stable and optimized production process, leading to greater success in the biogas industry.

For biogas producers looking to take their operations to the next level, NETZSCH pumps represent a sound investment in both efficiency and sustainability.

As a global specialist in conveying complex media, NETZSCH's portfolio includes rotary lobe pumps, multi-screwpumps, peristaltic pumps, grinding systems, and barrel emptying systems as well as progressing cavity pumps.

Thanks to numerous models, we cater to various applications in various process industries. Whether environment & energy, chemical, pulp & paper, food & pharmaceuticals, mining, oil & gas upstream, mid- / downstream , or batteries: We develop a customized and sophisticated pump solution for your inquiry.

Brochures

More news from NETZSCH Pumps & Systems

Brochure