24.02.2025

Learn More About Areas of Application for Multi Screw Pumps

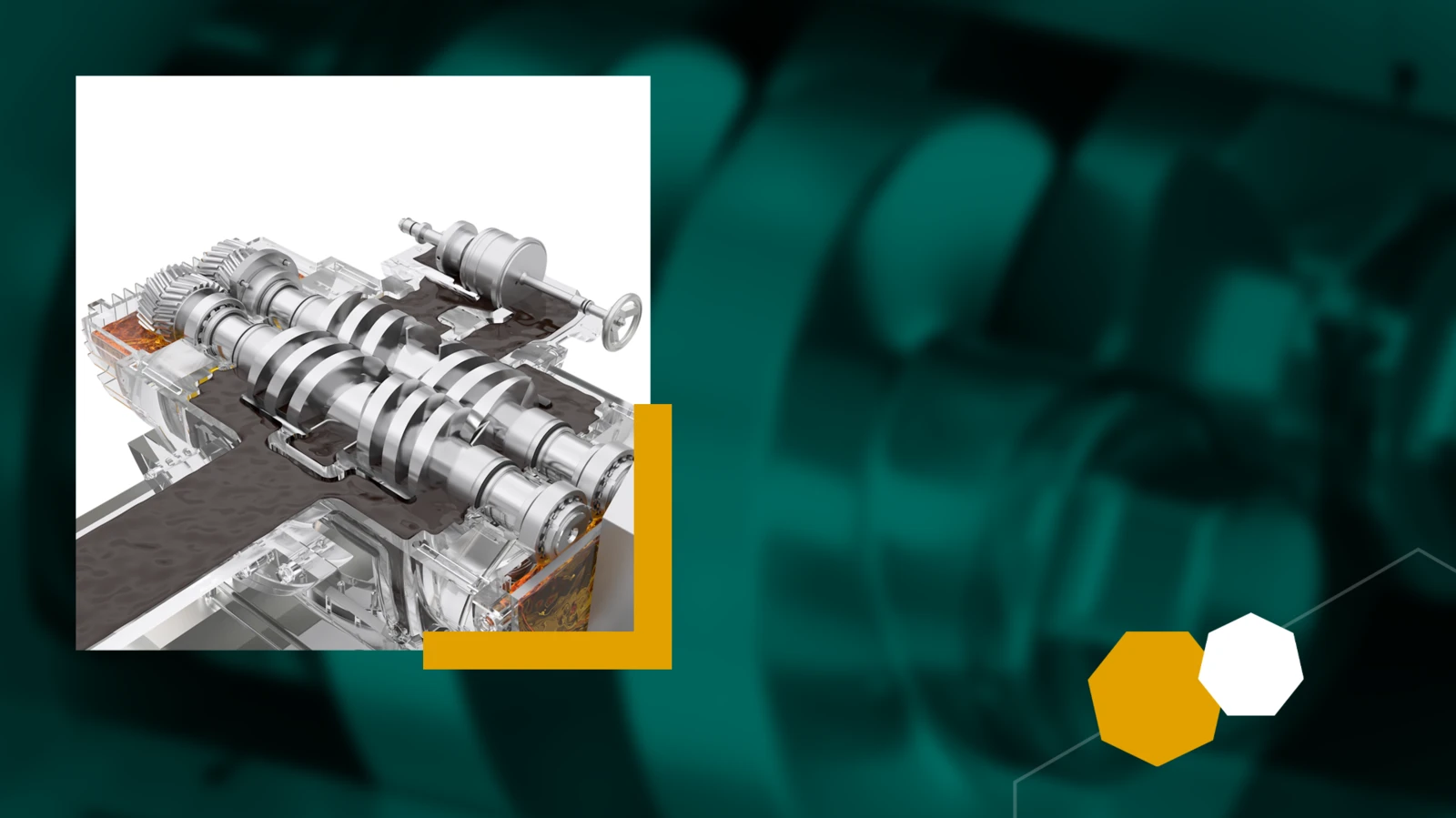

The multi screw pump is characterised by its ability to convey fluids evenly, efficiently and with slight pulsation. Thanks to its robust construction and high flexibility, it is used in various industries.

Multi screw pumps are among the most efficient and reliable pump systems when it comes to pumping viscous, abrasive or sensitive media. However, what are the specific industries and areas of application in which they are used? We provide an overview of the diverse areas of application for this pump technology and its advantages.

Customised Consulting

Industrial areas of application for multi screw pumps

Oil and gas extraction: Reliable performance even under extreme conditions

Multi screw pumps are essential in the oil and gas industry for safely and efficiently moving media such as crude oil, gas condensate and heavy oil, even at high pressures and temperatures. Their robust design enables smooth, pulsation-free pumping, protecting equipment and minimising maintenance requirements. Whether in drilling fields, pipelines, loading or as a lube oil pump, the multi screw pump's versatility and ability to perform under extreme conditions make it the ideal solution for demanding areas of application.

Chemical industry: Precision and safety for demanding processes

Multi screw pumps meet the high requirements of the chemical industry by pumping aggressive, viscous and sensitive media precisely, safely and efficiently. Their material resistance to chemicals such as acids, alkalis or solvents ensures a long service life and plant safety. Their pulsation-free pumping makes them suitable for many processes, from precise dosing of highly concentrated substances to processing large volume flows. Multi screw pumps can even convey shear-sensitive media gently without affecting the chemical composition. Due to their high efficiency, low maintenance requirements and adaptability, multi screw pumps are the preferred choice in the chemical industry to produce plastics, additives and other products with maximum safety.

Food and beverage production: Hygienic precision for sensitive products

Multi screw pumps are also becoming increasingly popular in food and beverage production, as they meet the highest hygienic standards and can handle sensitive media such as juices, yoghurt or oils gently and efficiently. Their ability to pump media of different viscosities without pulsation ensures consistent product quality, while their hygienic design meets the strict requirements of EHEDG and FDA. Smooth, easy-to-clean surfaces and CIP and SIP capability ensure maximum food safety. The flexibility of the multi screw pump enables its use in a wide range of application areas, from dosing liquid ingredients to conveying carbonated beverages.

Advantages of multi screw pumps

Multi screw pumps offer a variety of advantages, making them the preferred solution in numerous industrial areas of application. Even under demanding conditions, their efficiency and reliability make them the first choice in many industries. These pumps offer maximum efficiency and adaptability in the chemical or food industry or oil and gas production.

- Robustness: Their performance remains constant even under challenging conditions, such as high pressure or abrasive substances.

- Efficient pumping: Thanks to their innovative design, multi screw pumps convey media evenly and efficiently.

- Versatility: They can be customised for various media and applications.

- Hygienic: Hygienic versions are available for sensitive areas such as food and pharmaceutical production.

Get to know why NETZSCH pumps are the ideal choice

With the NOTOS® multi screw pump, NETZSCH Pumps & Systems, the global specialist in handling complex media, offers a solution designed to meet the highest demands. Our pumps are not only adapted to the specific requirements of your industry but also impress in all areas of application with the highest quality and durability. The proven technology ensures maximum efficiency and minimal downtime – a decisive advantage for your processes.

In addition, we offer a unique worldwide sales and service network. Our service and support do not end with the purchase. We are there for you, from advice and maintenance to spare parts, repairs, and modernisation. At NETZSCH, we know no limits when providing our customers first-class service.