HEAVY OIL

Cavitation-Free and Cost-Saving: How to Pump Heavy Oil Efficiently

Innovative pump technology revolutionises heavy fuel oil transfer in seaports

High costs to reduce viscosity and flow breaks due to cavitation are widespread problems when pumping heavy fuel oil. Efficient pumping is, therefore, not possible in many cases. A Brazilian seaport also struggled with these challenges until it became aware of NETZSCH Pumps & Systems.

With the global specialist in handling complex media, the operator could sustainably resolve its problems when transferring heavy fuel oil from tanks to ships or lorries and increase its reliability and efficiency. Discover why the operator contacted NETZSCH shortly after the successful commissioning and how to organise the transfer of heavy fuel oil more efficiently in the future.

Konsultasi Personal

Things to consider when pumping heavy fuel oil

Two centrifugal pumps transferred heavy fuel oil from the tanks to lorries or ships in a Brazilian seaport. Due to the viscosity, the system had a low NPSHa value caused by the temperature, especially at night. Accordingly, adding expensive diesel to the heavy fuel oil was necessary to reduce the viscosity. “With conventional centrifugal pumps, the poor suction behaviour results in residual quantities remaining in tanks that cannot be used”, explains Vitor Assmann, Senior Sales Manager at NETZSCH do Brasil. “Furthermore, cavitation can occur if the technology is unsuitable, causing the pump to break down in the long term.”

Pumping heavy fuel oil: Handling high viscosity and preventing cavitation

These were precisely the problems that occurred in the Brazilian harbour. Almost 3,000 litres of diesel were added daily to reduce the viscosity. Despite these measures, cavitation damage regularly occurred, which significantly impaired operations. The challenge was to cope with the high viscosity of the heavy fuel oil and to solve the cavitation problems of the centrifugal pumps. The tank farm requires a system that can transport up to 200 m³/h of heavy fuel oil at a pressure of 18 bar, a temperature of 10 to 50 °C and a viscosity of up to 9,000 cSt. The operators approached NETZSCH with this challenge. The aim was to increase reliability and efficiency and reduce energy costs when pumping heavy fuel oil. Therefore, the harbour operator decided to replace one of the two centrifugal pumps with a NOTOS® 4NS geared twin screw pump and to compare the two units.

How to increase your efficiency when pumping heavy fuel oil

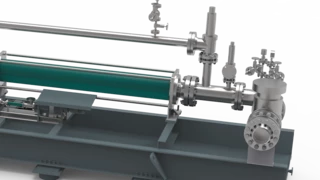

The multi screw pump from NETZSCH, which is suitable for highly viscous media with up to 200,000 cSt, proved to be the ideal solution. The multi screw pump offers an exceptionally high level of robustness, is insensitive to dry running and can be manufactured from materials specially selected for the application. State-of-the-art manufacturing technologies allow close tolerances between the dynamic and static parts. This reduces backflow. Combined with the flow-optimised geometry of the pump chamber, this will enable you to increase your efficiency in the long term. The pumps are customised to your application to achieve the best possible performance.

As the 4NS can be operated with high-viscosity media, diesel injection was no longer required when pumping heavy fuel oil in the Brazilian harbour. This reduced the operator's costs by USD 2,000 per day. In addition, this unit runs much more efficiently with such viscous media. As a result, the power consumption has been reduced by over 40 percent to 65 kw. Which also saved energy costs. Therefore, the operator of the seaport approached NETZSCH again only a short time after commissioning the multi screw pump and also replaced its second centrifugal pump. Do you also want to make heavy oil pumping more efficient? We will find the optimum solution to meet your requirements.

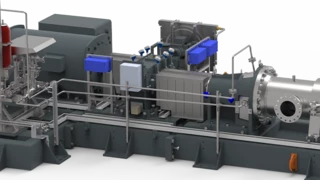

NOTOS® 4NS geared twin screw pumps

- Medium: Crude oil

- Capacity: Max. up to 200 m³/h

- Pressure: 18 bar

- Temperature: 10-50 °C

- Viscosity: Up to 9,000 cSt